Enough! You have finally had it with your water pump making so much noise that it might be better to let the plants die than to use the thing. There is really no need to put up with it. In this article we will provide ways to solve the problem–or at least, create a more livable environment.

What is Causing the Noise?

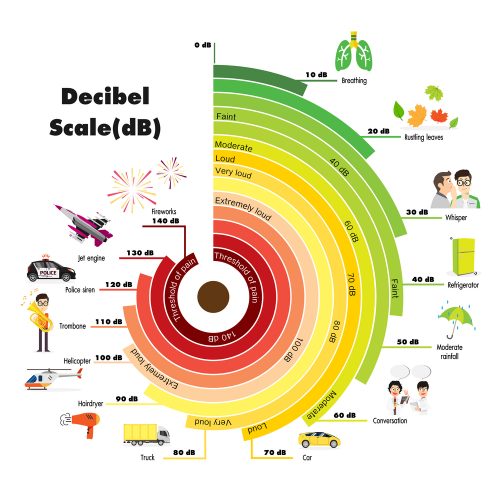

Before fixing the problem, you will need to know what is causing it. Do you have mechanical caused noise, location caused noise, operation caused noise, or a combination of any two or three of them. You might want to get a decibel meter and compare the reading to the following chart to see exactly what you are dealing with. On the other hand, if you, or your family, or your neighbors are annoyed by the sound, it does not really matter what the meter says. Someone is not happy and you need to fix it.

Types of Noise

Water pump noise falls into two categories–Airborne Noise and Vibration Noise (also known as Impact Noise or Structure-Borne Noise). For more detailed information on types of sound please go to Designing Buildings Wiki.

- Airborne Noise. Airborne Noise is sound that is transmitted through the air–like a dog barking, or the squeal of your water pump bearings about to seize up.

- Vibration Noise. Structure-Borne Noise is the result of an impact, or continuous vibration, on something solid–such as a floor, a deck, or a wall. Like someone walking across the floor above you, or your water pump vibrating against the fence.

Personal Note: For what it is worth, I consider all noise to be Airborne Noise because it is traveling through the air when it reaches your ears. For instance–your speaker causing vibrations in the air is not very different from your water pump causing vibrations on the deck. The noise all gets to you through the air. There, I feel much better now.

Mechanical Caused Noise

Mechanical Noises can be caused by any number of things, such as bearings, impeller, belt, pulley, among others. Hopefully, you still have the owner’s manual that came with the pump; or you should be able to download one from the manufacturer’s site. Regardless of the type of pump, there should be a ‘Maintenance Section’ that lays out a schedule, and what you will need to deal with. Make sure you perform the maintenance regularly. Get up close and personal with your pump. It will work better and last longer.

Note #1: I recommend a consistent maintenance plan–for all of your equipment. Every spring, I pick a weekend to do it all–oil changes, blade sharpening, inspections, and part replacement (if required). If you focus on each item one at a time–poking, wiggling, tightening, and fixing–it will likely last longer and work better. And you have a better chance of turning a potential problem into an avoided problem.

Note #2: Make sure that everything requiring lubrication gets lubricated with the proper product. Do not oil the drive shaft where it enters the pump housing unless specifically recommended. The oil could work its way into the bearing and dilute the grease, shortening the bearing lifespan.

Location Caused Noise

The location of your pump, and how it is mounted (or where you set it down) can have a significant impact on the noise it produces. Obviously, the further away from people that you locate the pump, the better. In most cases, you just cannot get it far enough away, and walking out to the back 40 to use it (unless you are watering cattle) is just too annoying. Also, setting it off-level on a hollow, empty dog house is just going to make the noise worse.

Operation Caused Noise

Some noise is produced by the operation of the pump such as motor hum, water passing through pipes, etc. Usually these noises cannot be changed. You will have to solve them some other way. Make sure your pump is running at the speed, and pumping at the capacity, it was designed for–and the hoses are the proper size. Incorrect hose sizes–both too big, and too small–for instance, will increase water pump noise.

Make sure your hoses are free of kinks or obstructions. Anything that makes the pump work harder will cause excess noise, not to mention extra stress on the unit, which will likely also shorten its lifespan. Anything that restricts water flow (things in the line, pulling hose tight around a corner, parking on the hose, etc.) will make the pump work harder, which in most cases will create more noise.

Water Pump Noise Cures

Now that you know what is causing the noise, here are some ways to fix it.

1) Mechanical Repairs

This is where your owner’s manual is essential. It should have a parts list with part numbers. Generally, you can order parts directly from the manufacturer, or if you are close to a pump supply outlet with a large parts department, they may have what you need.

Bearings

Water pumps (and most other motors) are designed to run at hundreds or thousands of revolutions per minute (RPM). Eventually, things wear out.

Usually after years of service, bearings will be one of them. Often, they begin squealing or clicking when they get tired. You may also notice grease leaking along the drive shaft. Or the drive shaft gets some play in it. None of these are a good sign.

Replace the bearings immediately. When you get the pump housing apart to allow access, take a good look at the drive shaft. If it is scared, pitted, or has grooves worn into it, you will probably have to replace the shaft also. Take a good look at the impeller. If it appears damaged, chipped, or worn; you might as well change it, too. If you do it all at once, you will spend more money–but know that you will get years of service without having to pull it apart again for some time.

Impeller

A broken, or damaged, impeller will also create more noise because it is no longer efficient. Damage is usually caused by sucking something other than water into the pump–such as dirt, sand, gravel, even leaves.

Unless you know that your water source is absolutely clean, make sure you have a proper filter (sand and dirt are pretty small) on the intake side of the unit. (Note: Check the filter regularly, and keep it clean. A dirty filter impedes water flow and increases noise.) If you know something got into the pump, stop using it immediately, disconnect everything, and flush out the system.

If you are not certain that did the job, you may have to take it apart to clean out the housing. Pain in the butt; better safe than sorry.

Belts and Pulleys

Many fuel-powered water pumps are not direct drive. The motor and pump are separate units with pulleys, belts, and clutches connecting the two units. If you have one of these, some of the noise could be coming from worn, loose, or poorly adjusted belts or cracked, loose, or chipped pulleys. Loose, worn, or stretched belts will also squeal because the drive pulley will be slipping inside the belt. Replace the belt with a new one.

Pulleys also can become loose, allowing the drive shaft to spin inside them. Make sure they are tight and in proper alignment. Non-aligned pulleys will shorten your belt’s lifespan.

Note: If your pump has a separate motor, you will also have to perform the required maintenance on it. Both units should be operating in top condition because problems with one will eventually cause problems with the other.

2) Fixing Location-Caused Noise

The option of locating your pump in the back 40 probably does not exist for most people, but whatever its location, it can be made quieter by how it is mounted. (Ground mounted is just a fancy way of saying ‘where you put it down before turning it on.’)

Level Your Pump

Not only will a level pump be quieter; it will also work better. Almost all pumps are designed to work best when in one position. Usually plumb, level, and square. Make sure the pump base is as level as possible. (Unfortunately, there is not much you can do about a concrete basement or garage floor.) Once the base is reasonably level, you may still have to do a little creative shimming to the pump base.

Note: See the next section–‘Isolate Your Pump’–for a lazy shimming tip.

Isolate Your Pump

To prevent Vibration Noise, you will have to isolate the pump from the base. I would use BXI Anti-vibration isolation pads. They are available in 2″ x 2″ x 2″ size or 6″ x 6″ x 2″ size. They claim to reduce Impact (Vibration) Noise by over 19 decibels–a truly significant reduction. Put one under each foot or corner of the pump, before strapping it to the base. Don’t worry about crushing them with a big pump. They have a maximum load rating of over 400 pounds.

Shimming Tip: The BXI pads are 2″ thick, and can be cut. Figure out how much you have to lower one or two corners of the pump to achieve level, cut down your pad or pads, and put them under the appropriate corners. (Most people think of shimming as raising an item to match the highest point. Just think of this method as ‘reverse shimming’.) Quick, easy, and works very well.

Have a Solid Base

Regardless of your pump’s location–basement, deck, garage, or out in the yard–it should have a solid base. Although not always possible, it is best if the base is permanent and the pump stays there most of the time. A permanent base can be made solid and level. Poured concrete is by far your best option; although paving stones, cinder blocks (with sidewalk blocks or 3/4″ plywood), even a wood platform will provide stability for your pump.

Once you have a solid base, and it is level and isolated (see sections above), screw, bolt, or strap the thing down. (If you are using metal straps, make sure you get some old carpet or thick underlayment between straps and pump housing.) Even a little vibration or torque can make it move around a bit, which might make it less level, or even kink a hose.

Note: I would make my wood platform about 4′ x 4′ square. Build a frame of 2 x 6 pressure treated lumber (for ground contact–not ACQ), two equally spaced joists inside the frame, covered with 3/4″ pressure treated plywood. 3″ deck screws for the framing, 2″ deck screws for the plywood. (Yes, I know you have an air nailer you want to use, but you really do not have to worry about shear strength here. And screws allow you to take it apart easily to modify it–if necessary.)

Note #2: For those of you living where the cold (35 degrees below zero at our house last week) will cause frost heaves, it might be best to use sidewalk blocks, or anything else you can re-level relatively easily every spring. Pouring a 4′ x 4′ x 6″ thick concrete pad that looks like a skateboard park jump every spring can be disheartening. Not to mention needing a backhoe to make it level again.

3) Operational Soundproofing

Once you are certain that your water pump is mechanically as sound as you can make it, you can move on to soundproofing the complete unit. Soundwaves travel in every direction from the source. Obviously, some sound-making equipment–like speakers–are more directional than others. But your water pump is an equal-opportunity noise maker. It will spread annoyance everywhere.

Build a Sound Suppressing Box

Here are 3 options for the type of sound suppressing box you can build. The basic construction principles are similar. But the final design depends on where, and how, you use your pump. Some pumps are a permanent fixture remaining in one location. Some are moved to a location for a season, or to do a big job. Some just get grabbed and used for a short time as needed.

The box you build will provide mass, damping, and gap sealing. Any box I build will require some, or all, of the following material:

- 3/4″ Good One Side plywood (birch or fir). One sheet should be enough for most projects. (Note: If the box is going to be left outside in all types of weather, you may want to consider pressure treated plywood. Not near as cute, but will resist water absorption and rot.)

- 2″ x 2″ common spruce. 40 lineal feet should be more than enough.

- Noico Red 315 mil (8 mm thick) sound deadening mat. One carton covers 20 square feet. Self-adhesive, easy to use.

- Acoustic Caulking. One tube should be enough.

- Wood Glue, 2″ screws, wood filler. As required.

- Optional Extras. Piano hinge. Locking castors. Handles. Latch. Hose quick couplers. Primer. Paint. Exterior caulking.

Basic Construction

Measure your pump and add 6″ in all directions. (You will need enough room inside the box to work–attach hoses, etc.) Cut plywood to required sizes, and assemble the sides using glue and a couple of #6 screws on each corner. Apply acoustic caulking to each corner, then apply the Noico to the inside surfaces. Construct a 2 x 2 frame flush with the top and bottom edges of the plywood; then add 2 x 2 to each vertical corner. Screw plywood to 2 x 2 framing. Stick more Noico Red on the inside of the top and attach to one side with piano hinge. Attach a length of light chain to the inside (to prevent lid from swinging all the way open), and a latch to hold it closed. Fill the screw holes, then prime and paint.

Note: Yes, I know that I am telling you to construct the box ‘backwards’; but I want to make sure my soundproofing material is as effective as possible and this is the easiest method of accomplishing that goal. Use a carpenter’s square before putting in the final screws to make sure you constructed a square box–not a rhomboid.

Provide hose and electrical cord (if necessary) access by drilling appropriate sized holes in the end panels, or cutting notches at the bottom. Either option will allow sound to escape because you really cannot seal them properly. (See Hose Access below for a solution.)

Box Construction Options

- If your water pump is bolted down in a permanent location, there is really not much more to do, other than fitting it over the pump. I would use angle brackets to attach it to the base, and run a bead of acoustic caulking around the interior where it sits on the base. (If the pump’s location leaves it open to the elements, seal the exterior of the box to the base with the best exterior caulking available.)

- If your water pump is only used occasionally, or for day projects, and will be stored inside after each use; then you can place it where you need it and set the box over it. Attach hoses and power as required and you are ready to go.

- This is my preferred choice for a soundproof pump box if it is not in a permanent location. Add a bottom to the box c/w Noico Red on the inside, screw it tight to the framing, and install locking castors on the bottom. Install a handle on each end for carrying, or a rope on one end for pulling. Place the pump inside the box and use duct hanging strap to securely attach it to the base. (Also, place a level in the box so you have it with you wherever you need it. Building the box this way allows you to easily transport it to where you need it. And, with the level, you can make sure it will operate as efficiently as possible.

Hose Access

I would find it endlessly annoying to have to run hoses and power cords through holes in the ends of my soundproofing box and attach them to the water pump every time I used the thing. The solution is actually quite simple. Extend both the inlet and outlet through the holes you drilled to the outside of the box. You can just leave a short length of hose exposed and screw on the lengths you need for the job. Make sure your attachment inside the box does not leak. Use Teflon tape if necessary. Once everything is installed to your satisfaction, seal the holes with acoustic caulking (if they are small enough), or cut strips of Noico Red and stick them around the pipes.

Note: I know you will get enough Teflon tape to last 2 lifetimes just to use a few inches. It will stop leaks inside the pump box. And it is cheap.

I would go one step further and add quick couplers to the exposed hose ends. They just make life easier. And reduce your stress level. There is also much less chance of disturbing the seal you have around the pipes. You can also extend the electrical cord through a hole in the box, and seal it with acoustical caulking.

Quick and Easy Pump Soundproofing

These suggestions work best for a pump that you grab and take to wherever you need it, use it until the job is done, and put it away again.

- Throw Up a Barricade. If you lean plywood on each side of the pump, it will stop a lot of the noise from travelling horizontally and direct it up. Annoying the seagulls can’t be a bad thing.

- Throw a Blanket Over It. Get a thick soundproof, fire resistant blanket to put over the pump. Tuck it tightly around the pipes and electrical cord. The blanket is really only practical for an electrical pump. They do not produce as much heat as a fuel powered pump; and there is no air intake to worry about.

- Place It Behind Something. Even placing it behind a hedge or fence will help cut down the sound. Or behind anything else in the yard that has mass. Garage, shed, above ground swimming pool, even the other side of your car.

End Notes

Buy a New Pump

Most water pumps have a 10 – 15 year lifespan. Less with poor maintenance. You may just have to bite the bullet, and buy a new water pump. If that is your decision, here are a few things to keep in mind.

- The volume you need to pump

- Size and weight

- Pump decibel level–when idling, and when pumping at full volume

- Warranties

- Ease of maintenance

Good ideas here. One caution is that many pumps should not be fully blanketed or wrapped due to containing the heat. AC compressors can be blanketed. Many have fins or vents just to transfer the heat from the electric motor. Then there is the warranty issue – you may void the warranty as the increased heat may lead to early failure. Check first then act..

Hi George,

Thanks for the info.

Terry

Hi Gary,

Sorry, I had a brain cramp with your name.

Terry

Thanks for the article and it’s info

I rented a studio flat

Land lord kep beside my window water pump

I’ve used the bxi-anti vibration isolation pads

It minimizes the water pump “vibration” noise but to minimize the noise itself and I’m not sure with what to cover to avoid heat blockage and keep it expose to air

Would a foam box with few wholes for air passage works?!

However, take care and thanks

Ali Issa

Hi Terry, I live in a 4 story condo above the pump room on the main floor. The pumps pump the hot water throughout the building for the infloor heating. This year the pumps started making a very audible hum. Had them rebuilt, still humming. Thinking of soundproof boxes. These pumps permantly installed in 4″ horizontal piping that rests about 4″ off the floor. I was thinking a box with legs with a cut arch to stand over the pumps and the piping, would add air flow vents. The issue would be still open at the bottom, I don’t believe we can seal the box around the piping and the floor. We woud need handles on the box to lift off for servicing. Do you think this would have an impact for the noise level? If i could cut down by half, my life woud be so much better. Appreciate your advice.

Hi Terry, Garry

How do we sound proof if we can hear loud water running, pumping, vibrating, and sounds like landing as well. We can hear from basement to upstairs.

Thank you very much

Chantal