Are your baseboard heaters keeping you awake? Does the pinging, clicking, and other noise cause you some concern? There may be several reasons for noisy baseboard heaters. However, most sounds don’t mean your heating system is going to fail.

Noisy Baseboard Heater: How to Make It Quiet: Regular cleaning and maintenance will keep your heaters working longer. Straightening the fins to stop pinging, adjusting mounting screws to stop clicking, ticking and humming, lubricate seams and overlapping components to end popping, and bleed air bubbles to quiet banging, gurgling, and trickling sounds.

In this article, we look at attached electric and hydronic baseboards, how they work, types of noises they may make, and how to silence them. After reading this article, you’ll have a better understanding of what the sounds are telling you, and how to get years of quiet warmth from your baseboards.

For information about quieting some other home heating problems, please see our articles How to Quiet a Noisy Furnace Blower, How to Quiet a Noisy Air Return.

How to Silence Noisy Baseboard Heaters

Silencing some baseboard heater sound is achievable in most situations and doesn’t require the skills of an HVAC specialist. However, some noises may be beyond your skill set and do require some expertise.

Sounds common between electric and hydronic baseboards have the same repair. Once you’ve identified where the sound is coming from, and have decided to quiet it yourself, turn the power off at the panel, gather your tools, and get started.

Electric Baseboard Heaters

Pinging

When the metal vanes touch, they produce a pining noise when heating up or cooling down. Remove the front cover, so the vanes are visible. Inspect the metal fins for damage. If some are bent so that they touch, they need to be gently straightened, so they no longer come in contact with each other. Do not break or cut them, or dislodge them from the heating pipe.

Use a universal fin-comb or a metal or plastic putty scraper with a 1-inch wide blade to separate and straighten the thin wafer-like metal. Begin at the least damaged end and work toward the most bent. Once all are separated and no longer touch, turn on the power.

Note: if the fins are bent, and it is impossible to separate them, consider replacing the heater.

Clicking, Ticking or Humming

Clicking, ticking, and humming noises coming from a baseboard have similar causes, the expansion and contraction of metal during heating and cooling down. Check that the heater hasn’t been painted, glued, or stuck to the wall. If it has, separate with a utility knife so it can move – that may solve the noise. Also, make sure no furniture or toys are jammed against or in the baseboard.

Another solution is to remove the front cover of the baseboard and locate the mounting screws. Loosen each a quarter to half a turn to allow the metal to move more freely. Tap the heater with your hand to make sure it has some movement.

Adding high-temperature washers or spacers between the wall and unit, or screw-head and unit may help. There should also be a 1/8” space between the baseboard and molding for expansion too.

Popping

Popping is also caused by metal expansion, but usually by metal pushing against and popping past other metal components such as seams, joints, or end caps. Remove the covers and apply or squirt a silicone-based high-temperature grease where metal may bind or rub. You may need to reapply the lubricant yearly or every other year.

Buzzing

A buzzing electric baseboard has two possible causes. If it’s a new install, check the power rating and supply voltage. If the heater is 120-volt and supply is 240-volt or vice versa, flip the breaker and replace the heater with a unit with the correct power rating.

If the power and supply voltage match up, there’s a good possibility the wall isn’t flat, and the baseboard element is touching the back, causing a vibrational buzz. Remove the cover and back-off the screws.

Tap or pat the unit with your hand to get it to straighten. You may need to add high-temperature spacers between the wall and heater back to keep it from warping.

Water Baseboard Heaters

Hydronic baseboards share noises with their electric cousins, and the repair is the same. However, the liquid they contain and use can cause some different noises.

Banging

A banging noise is caused by the build-up of air pressure and the liquid being forced through an air dam. Hydronic baseboards have an air pressure release valve on each heater to remove air from the system.

Remove the endplate and locate the valve. If you have the manual, follow the manufacturer’s instructions. Run the heater for 10 to 15 minutes. Place a bowl or rag under the valve to catch any drips.

Use a rad key, screwdriver, or pliers and turn the valve counter-clockwise. Bleed the air from the system and then close. This may also stop gurgling or trickling sounds too. You should bleed air from the system once a year.

Gurgling or Trickling

Gurgling and trickling sounds due to air bubbles or pressure can be solved by opening the pressure release valve and bleeding the line as you would for a banging noise. If it isn’t solved by removing air bubbles, it may be due to low pressure.

Check the pressure gauge on the unit or boiler against the owner’s manual. Follow the manufacturer’s instructions to adjust the pressure. Another possible solution is to check the level of the baseboard. If it isn’t level, it may make a gurgling or trickling sound. Adjust the wall mounting screws or feet to put the unit in level.

Knocking

Knocking is usually associated with hydronic baseboards connected to a central boiler. It is often heard as the heated fluid moves through the supply pipes. If the holes for the pipes don’t allow room for expansion, they expand and bang against joists or studs.

If the noise isn’t in the wall or floor, but at the unit, remove the end cap where the supply pipe connection is. Buy or make a 3-inch pipe spacer out of thermal foam or plastic. Slide it into the hole in the wall or floor around the delivery pipe. It will stop the noise at that location.

How to Keep Your Baseboard Heater Working Efficiently

Regular maintenance and cleaning will keep your baseboard heaters working efficiently for years. Wipe and vacuum the dust off the heater and out of the fins. Be careful not to damage the fins, though.

Bleed air out of hydronic baseboard systems at the beginning of each heating season too. Open the louvers to permit heated air easier movement into the room. Regularly check inside the heater for children’s or pet toys that may have become lodged inside the cabinet.

Heaters draw cool air from underneath, so keep carpets, furniture, toys, and pet beds away from the heaters for good airflow. Make sure the unit has half an inch between it and the floor if it doesn’t have feet.

Curtains should not cover baseboard heaters. There should be at least a 4-inch gap between the top of the heater and the bottom of the curtain.

Install an automated digital wall thermostat. It will help maintain a more consistent temperature and improve the operation of the heater. Consider setting the temperature at 68°F and wearing slippers.

Install energy-efficient windows or cover windows with thermal film to decrease drafts. Baseboards radiate heat into the area they occupy; they don’t blow heat into adjacent spaces like hallways. However, a door will prevent air movement and help maintain the temperature within a room.

Types of Baseboard Heaters

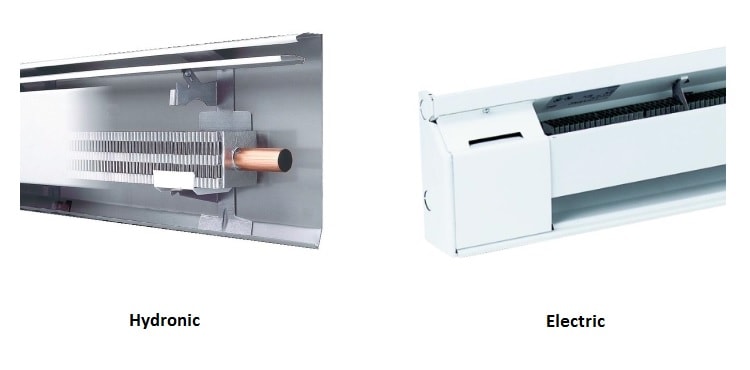

Electric and Hot Water (Hydronic) are two types of independent baseboards used for heating homes and offices that are part of the built-in heating system. They may be the primary heat source or an auxiliary one. These are not the portable space heaters; they are attached to the wall or floor and hard-wired into the building, and operate on 120 or 240-volts.

Other types require a boiler and are connected with pipes through walls and floors and radiant heat from a central boiler. Baseboard heaters are located under windows or near doors and heat the cool air as it falls or flows from the less insulated opening, minimizing drafts.

Baseboard heaters commonly don’t have fans to push the heat around the rooms like forced air heaters; they radiate the heat into a room. Cool air enters at the base of the unit, flows over the heated surface, and rises into the room.

The heated air forces cooler air down to be warmed, creating convection current type circulation. They slowly heat the air without blowing dust, pollen, dander, and other allergens around. With no moving parts, they are also usually quieter than fan driven central heating plants.

Some units have a built-in thermostat. However, the more efficient ones have a wall-mounted thermostat for more accurate room temperature control. They heat living and working spaces instead of whole buildings.

Electric Baseboard Heaters

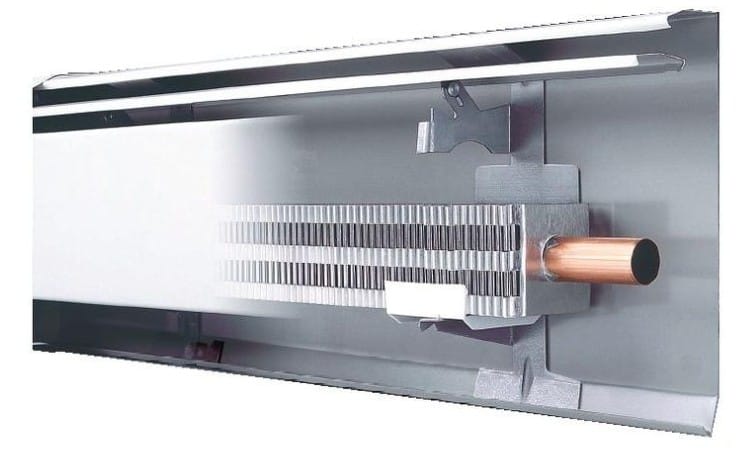

Electric baseboards have a built-in element and thin metal fins. The element may be inside a single metal pipe or a long flat ‘zig-zag’ type coil. The coil threads through thin wafers of tin, aluminum, or steel.

The wafers heat quickly and provide a greater surface area to radiate heat into a room. When space is heated, the thermostat shuts the heating element off, and the baseboard cools down quickly. Cranking up the thermostat won’t heat the space more quickly; it just increases your energy bill. Every degree above 68°F is an increase of about 5% on your bill.

Hot Water (Hydronic) Baseboard Heaters

Hydronic baseboard heaters have an electric element inside a metal pipe that is filled with water, oil, or another liquid. Unlike boiler systems that have pipes running through walls and floors, hydronic baseboards are self-contained heaters.

The element uniformly heats the water or oil, which in turn transfers the heat into the air. The mass of the water or oil retains heat long after the thermostat shuts the element off, decreasing fluctuations in room temperature. So, they are more energy-efficient than their electric counterparts.

Forced Hydronic Baseboard Diffusers

Forced hydronic systems require a boiler and circulation pumps to produce and move the heat. Baseboards diffuse the heat into a room, not create it. Thermostats control the delivery to the baseboard, and small pumps move the heated fluid where required. The same system is used to provide radiant heat for floors, swimming pools, towel rails, and even to melt snow on driveways.

Baseboard Heater Noise Types

Baseboard heaters have few moving parts, so they don’t make much operational noise. However, some common sounds may be heard, and others that are less common, which provide information about potential problems the heater may be developing.

Pinging

Many electric and hydronic baseboards produce a pinging sound. It is commonly caused by the expansion and contraction of the thin metal vanes within the baseboard as the heat or cool. The baseboard heater noise is greater if some fins have been bent and rub each other as they expand or contract.

Clicking

Baseboard clicking can have two causes. If you hear the clicking as the unit heats up or cools down, it is the metal adjusting to the temperature changes. A clicking sound that occurs only when the heater turns on or off is a switch relay. It may come from the baseboard, or from the wall-mounted thermostat.

Banging

Hydronic baseboards can develop air bubbles, which create air pressure. As the pressure builds up, it causes a banging sound within the heater’s or delivery pipes as the liquid forces through the air blockage.

Ticking

The sound the heating rod inside the heating tube makes as it heats up or cools down.

Gurgling

A gurgling inside the heater or supply pipes is often caused by low pressure in the boiler. The sound may also be caused by air inside the unit or system. It may also be due to the heater being out of level.

Trickling

A trickling or running water sound may indicate low pressure in the system, air bubbles in the system, or the baseboard not being mounted level.

Humming

Humming from the baseboard may be the result of a pinched part of the metal housing. It may have occurred when a wall was being painted, or the unit may have been banged by furniture being rearranged.

Popping

Popping is a baseboard heaters noise that may occur when the baseboard is heating up or cooling down as metal components shrink or expand and ‘pop’ back into place.

Buzzing

A buzzing sound is associated with electricity and may be the result of a power supply incorrectly matched with the baseboard, especially on new installations. Another possibility is that the heating pipe or vanes are touching the back of the baseboard housing due to a curvature in the wall. When the element heats, it causes the metal to vibration against the back, causes a buzz.

Knocking

Hydronic systems may have a knocking sound when hot liquid displaces cool or cold liquid causing the metal pipes to expand and knock.

Baseboard Heater Making Noise When Off

Hydronic baseboards that are connected to a boiler may continue to produce sounds even when the system is off-season. Some boilers continue to circulate liquid, and cool liquid in a warm room can even have expansion and contraction noises. Changes in pressurization during the off season can also cause sounds.

Electric baseboards shouldn’t make any noise when off. However, some basement, bathroom, or garage baseboards have on-board thermostats that prevent them from going below 40°F to avoid freezing. There may be a clicking sound as it checks the temperature, but unless it’s below that temperature, they shouldn’t turn on.

Conclusion

Electric and hydronic baseboards are common ways to heat rooms, homes, and offices. Knowing how they work, and how to quiet noisy baseboard heaters is important, especially if you have one. Whether it’s a banging, clicking, gurgling, humming, pinging, popping, ticking, or trickling noise, discerning what it means and how to stop it is essential.

Hopefully, you have a better understanding of how to quiet and maintain your baseboard heaters. If you thought the article informative and helpful, share it with others who may be interested. Please let us know if you liked it, and share your comments and any suggestions.

You May Also Like:

Wonder if you can help here. Installed hydronic baseboard heating and a single wall hung a/c in a space remodeled for me. Pipes are in wall. Moved in April of this year. There is low to loud bangs on the one outside wall. Installer said something about something (don’t remember words) not being secure; will require opening up wallboard. No idea where I would put the chest, rug, desk, etc., that would have to be moved to do that or how to avoid dust on my sofa, etc. Small room. Left for now. Now last week, the heaters in the bedroom started making noises. Waking me up anywhere from 2am to 6am plus. This concerns me as I will be 87 in December; already have hip/spine pain issues that make me wake to change positions. I know this is not good for my health. Sometimes I can go back to sleep only to be awaken again by the noise. I don’t even try if it is after 6am. Tech couldn’t find problem. The first sound I heard was (best explanation is a low sound of water moving in kettle prior to it coming to a boil and then a bang. Some low and some loud. Any idea?? So hope so. I am tired and the installer doesn’t seem interested.

Hi Eugene,

My baseboard heater in my condo sound like someone is dropping a marble on the floor and it bounced up and down.

What would be the reason? I am so glad I am finally moving out of here next month.

Hi France,

My guess is that it happens when the heat comes on it is the pipes warming up and expanding. You will hear it again when the heat cuts out.

Terry

Terry,

I have the marble issue as well in our master bedroom. Do you have a recommendation to fix this noise? Thanks,

Andy

Hi Andy,

Unless you can get to the pipes and strap them to the framing or floor, I think you are stuck with it. If the pipes are coming through the floor or face mounted you might be able build a little box over or around them.

Terry