When I was looking into soundproofing my basement and making acoustic absorbers, I wanted to know “is Styrofoam good for soundproofing?” It’s light-weight and has thermal properties like fiberglass, but gets a big “Boo!” from acoustic gurus around the web. I wanted to know why, or why not, so I went looking for an answer. After much reading and even more coffee, I decided to share so you can make an informed decision too.

Is Styrofoam good for soundproofing? Styrofoam is not good for soundproofing. Used by itself as a sound conditioning panel it doesn’t do much, however, molded into a quadratic diffuser or laminated to denser material, and it improves sound quality. When used with denser materials that have greater mass, its soundproofing characteristics decouple and absorb with excellent results.

What is Styrofoam?

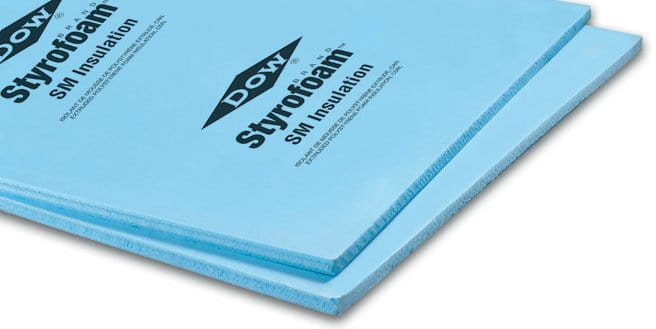

Styrofoam™ is closed-cell polystyrene petroleum-chemical formulation foam that is extruded to form panels. It is wrongly applied to expanded polystyrene foam used to form products. It is a trademarked brand that is used interchangeably by the public for different products and brands made of similar material.

Extruded Polystyrene insulation (XPS)

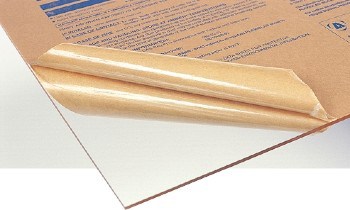

Extruded polystyrene foam (XPS) we commonly see as blue or pink panels of rigid impact resistant insulation is used primarily in the construction industry. The surface is smooth, and it is impervious to moisture penetration.

XPS is manufactured using polystyrene beads that are heated and mixed and pushed or extruded out to form a continuous stream of foam that hardens as it is exposed to air. The stream is trimmed and cut into smooth surfaced thermal panels that are durable and strong.

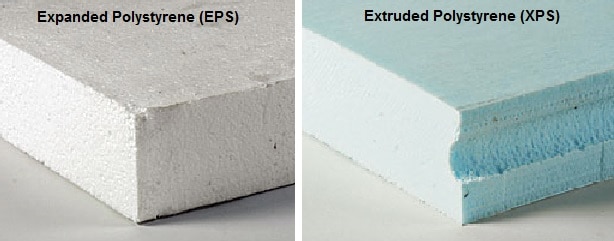

Expanded Polystyrene insulation (EPS)

Expanded polystyrene foam (EPS) is often white and is used to form thermal (coffee) cups, coolers, craft supplies, and packaging materials. The surface is slightly rough, and individual polystyrene beads can be seen and removed. It has low moisture or vapor permeability.

EPS is made by infusing steam or heat into a mold containing small polystyrene beads. The heated beads expand and fuse to form the shape of the mold. The product is a closed cell, but some airspaces or voids that make it potentially permeable.

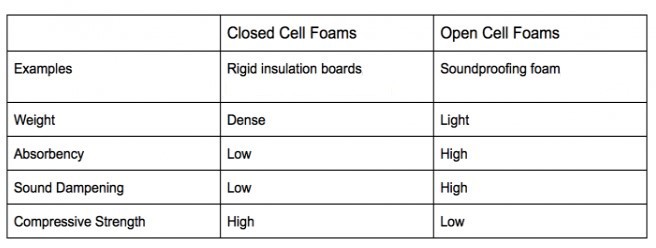

Open Cell vs. Closed Cell Polystyrene

Open cell foam is porous, and air and moisture can pass through, so it requires a vapor barrier. The cells are different shapes and sizes, and their walls are broken, which makes it softer and flexible. Its R-value per inch is about 3.5.

Closed cell foam is not porous so air and moisture can’t pass through, so no vapor barrier is needed. The cells keep their shape and are similar shapes and sizes.

The unbroken cell walls make them more rigid and hard. Air is trapped between the cells making it a better thermal insulator. It has an R-value of around 6.5 per inch.

Open cell foams weigh between 0.4 and 1.2 lb/ft³ and closed cell closer to 3 lb/ft³, making them stronger and denser. The denser material has a higher thermal insulation value. However, open cell foam is a better sound absorber due to the open cell permeability. Some sound waves get trapped within the open cell format and absorbed.

What Is Soundproofing and Sound Absorption?

Soundproofing is the attempt to prevent sound from passing into or out of a space using noise reduction and absorption. One or more layers of material are used to reflect or absorb sound waves and decrease its transmission. Sound absorption is how a material controls sound by absorbing the sound waves and converting some of the energy to heat, so fewer waves pass through – effectively reducing noise.

Soundwaves travel through the air until they encounter a barrier that reflects or absorbs it. The characteristics of the material determine how it will interact with the noise.

Expanded polystyrene (EPS) is a good thermal barrier, but by itself is a poor sound barrier. Although it has sound absorbing characteristics, it doesn’t have the mass, so it won’t be an effective acoustic panel to hang on a wall.

However, EPS is effective when used with other materials to construct a sound barrier. It has other qualities that come into play when it is used in wall construction that effectively decrease sound transmission through walls.

The use of EPS within partition walls decreases the transmission of sound through the wall by absorbing it and decoupling wall layers.

A standard 2”x4” wall with 1/2″ of drywall on each side has an STC (sound transmission class) of 35. If you stand on one side, you’d be able to hear a normal volume conversation on the other through the wall, but not make out individual words.

However, the sound is still disruptive. Adding a 2” layer of EPS into the cavity so there is a 1-1/2” air space left, will improve the STC rating of the wall 5 or 6 points to 40 or 41. That will make a conversation inaudible and loud conversation a murmur. Other wall finishing techniques and materials can increase that to an STC of 52.

Is Styrofoam Good for Soundproofing?

There are many articles on the internet that state Styrofoam (EPS) isn’t much good for soundproofing. Some actually say it sucks.

They want to hang it on the wall because it’s light and expect it to absorb or diffuse sound. All this shows is that they aren’t applying the principles of soundproofing.

The four elements of soundproofing are decoupling, adding mass, absorbing, and damping sound. Styrofoam has characteristics that make it a good thermal insulator like fiberglass and stone wool, but it doesn’t have the mass that they do to absorb as much sound.

However, EPS does have decoupling and absorbing characteristics that make it a good soundproofing partner.

Using polystyrene in wall construction helps to reduce and muffle sound transfer through walls. It helps to decouple the wall layers, absorbs and reflects sound waves, and decreases transmission through the barrier. It is more effective at minimizing mid to high-frequency sounds as it doesn’t have the mass to absorb low frequencies.

Does Styrofoam Absorb Sound?

The properties that make Styrofoam a good thermal insulator should also make it a useful sound insulator. Unfortunately, EPS doesn’t have the mass needed to make it a good noise blocker by itself. However, when attached to drywall, MDF, or even concrete, it excels at blocking sound transfer.

When used in standard interior wall construction Styrofoam can help raise the STC rating over 40. If the wall construction includes mass loaded vinyl and Green Glue, the use of EPS can improve the same wall to an STC over 50. The polystyrene works as a partner to decouple and absorb, helping to prevent sound movement.

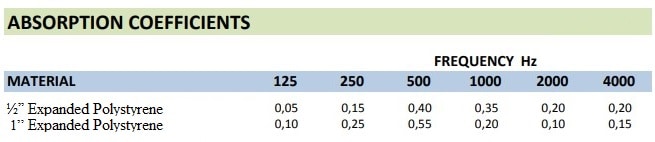

Polystyrene Sound Absorption Coefficient

The noise reduction coefficient (NRC), coupled with the sound transmission class (STC) are values used to identify the effectiveness of a material at blocking or absorbing sound. The NRC is a number between 0.0 and 1.0 that shows a products average noise control of frequencies between 125Hz and 4,000 Hz. The thickness and density of material influences its ability to block or absorb sound.

Styrofoam is a building material and is lightweight and not very dense. The best sound absorption rating, or NRC, I was able to find for polystyrene was 0.20.

EPS performs better at mid to upper sound frequency attenuation, and significantly better when used with other materials. Polystyrene 25 has an NRC of 0.59 at 2500Hz; low-frequency performance isn’t as good though.

Practical Uses

Using polystyrene in wall construction will improve your soundproofing efforts. When combined with other materials, EPS performs as a decoupling barrier and improves better as a sound absorber. It’s sound properties work best when paired with other materials.

Window & Door Plugs

Making a plug to improve the sound abatement of a window or door is another way to soundproof a recording studio, office, or media room. Polystyrene is lightweight, resistant to moisture and mildew, and is a good decoupling layer for in window and door plugs. Attached to MDF panels or frames, it partners to soundproof an interior space effectively.

Structural Insulated Panels (SIPs)

Structural insulated panels are being manufactured for the building industry in controlled factory environments from polystyrene panels sandwiched between two layers of OSB. The ESP decouples the wall layers, provides thermal insulation, and prevents the sound transfer, while the OSB provides the rigid framework.

Acoustic Sound Diffusers

Styrofoam is molded into different shapes, including 13-root quadratic diffusers. They are available for use as ceiling tile or as ceiling or wall panels to diffuse frequencies between 600Hz and 5,000 Hz. They help to break up and disperse soundwaves, to reduce reflection, and also to absorb some waves and converting them to heat.

Alternatives – Better Soundproofing Materials

There are alternatives to soundproofing with Styrofoam which are heavier and denser, so have more mass and perform better at lower frequencies too. A good article with more information is The Best Soundproofing Insulation.

Roxul – Stone Wool is common construction insulation that is frequently used in sound absorbing panels. Available in battens and rigid panels, it has an NRC between 0.85 and 1.05 and can be used in walls or used in hanging acoustic panels to improve sound quality. It can also bump the STC of a wall to a rating of 52 or better.

Fiberglass Insulation – is another construction insulation material available in batts and rigid panels. It can improve the STC of a wall to 53 and has an NRC rating between 0.85 and 1.05.

The batts can be used in walls, but are not as rigid as other products. The rigid panels of can be used in walls or wrapped and hung as acoustic panels.

Conclusion

Styrofoam is a good thermal insulator but independently isn’t weighty enough to use as a sound absorbing panel. It needs to be used with other heavier materials to be an effective sound attenuation material.

I hope you found this article informative and of use in your pursuit of a quiet space. If you know someone who might be interested in the content, pass it on. Your comments and suggestions are appreciated too.

Related posts:

Great info!

I am looking to soundproof my garage for the purposes of band rehearsal. Obviously the easy annoyed neighbors don’t want to hear *any* of it. I am removing the garage door and making it a non-garage.

My garage is already finished on the inside and I assume there is the normal amount of fiberglass insulation in the walls. I blew in cellulose loose-fill into the attic space.

My plan was to install pink extruded styrofoam on the interior walls and ceiling then 3/4 drywall over that giving the foam more mass. Then cover the entire walls and ceiling with foam tiles to deaden the sound.

Do you think this will be enough to keep it silent on the outside of the structure?

Or do I add the pink extruded foam and drywall, and then build a seperate insulated wall with air space between it and the existing wall and then hang the foam panels on that?

With all this insulation I assume I’ll need to install some air vents with very long and winding insulated ducts….

Hi Jamey,

You are making the right choice with the door. They are horrible to soundproof. And with the cellulose. But Styrofoam is going to be a waste of money and time. If you are not going to build room within a room, use Mass Loaded Vinyl on the walls. Then I would use 3/4″ plywood (adds mass and you can screw anything anywhere you want), with Green Glue sandwiched between 5/8″ soundproof drywall (QuietRock or Certainteed). After painting, then add your acoustic treatment. If the existing wall is insulated, you can build a room-within-a-room without doing any more to it. Just make sure you leave at least 1 1/2″ dead air space between walls. For lots more information on all of that please see our articles: How to Soundproof a Garage, How to Build a Soundproof Room-Within-a-Room, How to Sound Treat a Room.

Hope that helps,

Terry

What is the best way to soundproof a bedroom window? I live in a noisy neighborhood with barking dogs and truck engines. Wondering what is the best material to use. I don’t care about looking out the window.

Hi Cameron,

Here are a few suggestions – roughly in order of cost.

1) Hang a thick moving blanket over the window. See our article Soundproof Blankets for Windows.

2) Build a window plug using 2 x 2 and Roxul soundproofing insulation.

3) Buy an AcousticCurtain from Residential Acoustics. Blocks 21 – 25 decibels.

4) Buy Shuteye Acoustical Shutters. Blocks up to 50 decibels of outside noise.

Hope one of these will give you a little peace.

Terry

Hi Terry!!

Informative article, thanks for the info.

Question:

I have a bedroom studio, and want to decouple my near field monitors from my table / desk.

Would using a 2″ styrofoam base with concrete ‘bricks’ on top (under the speakers) be adequate?

Hi Michael,

I do not think the Styrofoam will provide enough isolation. I think you will still have vibration from the bass frequencies. For under $30.00, depending on size, you can get 2″ thick heavy foam speaker isolation pads from Amazon.

Terry

For sound absorption, I am building walls with 5/8” drywall, sonopan under that, then 2 1/2” eps. There will be a 1/2” gap. Should I put it between the sonopan or behind the eps for best sound absorption?

Hi Greg,

Sonopan’s website seems to suggest 1/2″ resilient channel between the Sonopan and the drywall.

Terry

Hi Terry, I’m replacing my vinyl siding this year and was thinking of insulated vinyl siding to help with freeway noise, but haven’t found much supporting evidence. Any advice or links to share for absorbing/reflecting sound on exterior of house? I thought about adding MLV to outer wall, but don’t want to create a double vapor barrier. Thanks!

Hi Dennis,

I have never found an insulated siding–vinyl or aluminum–that has figured out how to eliminate the gaps where the panels join. You are not going to get complete coverage for soundproofing or insulation value. I would install 4 x 8 sheets of 3/4″ foil-wrapped polycyanurate foam. Tape the seams and install your siding. Whatever you put on the wall will have a chance of creating a double vapor barrier because you want it tight for the soundproofing. If houses are 10 years old or more, I do not worry much about it. They should be dried out.

Polycyanurate is much denser than polystyrene–giving it more mass for soundproofing.

Terry

Hi Terry,

I enjoyed reading your article. My son is working from home and his desk is in the basement. We have two noisy dogs that can be heard when he is on the phone with customers. We have ordered a Safe and Sound door which we will install and which should help with sound. We were also hoping to do something to the stairwell walls to reduce the sound coming from upstairs. Would sheets of styrofoam attached to the outside of the existing drywall in the stairwell work to reduce the sound entering that part of the basement? Any suggestions would be appreciated.