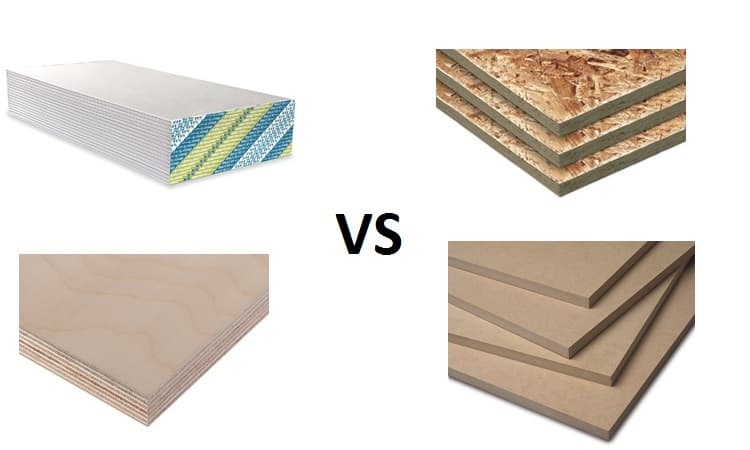

I live in a very noisy area, but I needed my office to be very quiet and block out the external noise. This got me wondering, drywall vs OSB vs plywood vs MDF for soundproofing: which is better? After thorough research, I have some interesting findings that I’d like to share with you.

Drywall is the most cost-effective and the most noise-reducing since it has the most mass. Plywood is the least effective since sound transfers quickly through the wood. OSB and MDF have similar soundproofing characteristics as drywall, but they have other drawbacks that make them a less optimal choice in many situations.

Although they have similar abilities to block noise, these materials all have their own strengths and weaknesses that make them more or less applicable for building a soundproof wall. None of these materials on their own will be soundproof. Let’s discuss the benefits of one material over another, and some ways to make them more effective at reducing noise.

Principles of Soundproofing

When trying to make a wall or other structure soundproof, there are four main principles to take into consideration. These are:

- Mass

- Absorption

- Damping

- Decoupling

On their own, each of these principles of soundproofing is only moderately effective. To reduce sound transmission, you’ll need to combine the effects of several or all of these concepts. Let’s take a look at what each one is and how we can improve them for more effective soundproofing.

Mass

Mass is the amount of material between your sound source and the area you are trying to keep quiet. For sound to pass through a wall or other surface, it must cause it to vibrate. The more material that it must vibrate, the heavier it will be, making it harder to cause these vibrations.

The most simple way to increase the mass of a surface you wish to soundproof is to double layer it. If you’re building a wall, you would use two layers of ⅝” drywall to create the most mass. If you were building a soundproof box for a compressor, you would build one box inside of another to increase the mass.

While increasing mass does improve soundproofing abilities, it’s not enough on its own to make something soundproof. On a standard, single-stud wall, doubling the layer of drywall will result in a noise reduction of about 5db. For a little perspective, a normal conversation is about 60db.

Absorption

Absorption is how much of the sound’s energy gets reduced as it passes through the wall. This will be taken care of by a low-density medium such as fiberglass insulation in walls. If you were building a soundproof box for a compressor, absorption may be performed by styrofoam or even sound control foam.

Damping

Damping is the most effective soundproofing principle for low frequencies. This is a layer that will be added between two stiff panels such as drywall and acts to stop vibrations by converting their energy into heat.

Green Glue noise proofing compound is currently the most effective dampening agent, and it will be discussed more in-depth later in this article.

Decoupling

Vibrations are most effectively carried out through physical contact. Decoupling is when you put space in between the separate parts of a structure so that they can’t transfer vibrations directly.

To achieve decoupling in a wall, you would stagger the studs so that the inside and outside drywall are attached to different sets of studs.

How is Soundproofing Measured?

The noise reduction characteristics of different materials are measured on a scale called the Sound Transmission Class or STC levels. The higher a material’s STC rating, the more sound it blocks. A standard wall will have an STC rating of 35-45.

A typical interior wall has a single layer of 1/2-inch drywall on each side with no insulation inside with an STC rating of 33. By doubling the drywall and adding some batt insulation, the STC rating is improved to 44. A reduction of 10 STC levels results in an apparent sound reduction of 50%.

Drywall vs OSB vs Plywood vs MDF for Soundproofing

Although each of these materials is very similar in terms of soundproofing effectiveness, they have very different qualities that make them more or less suitable for different applications. Here we will look at each material more closely and see how they stack up.

Drywall

Drywall is the most cost-effective option and is the go-to choice for double layering walls. This is in large part because it is much more moisture resistant than the other materials.

Drywall is the most cost-effective option and is the go-to choice for double layering walls. This is in large part because it is much more moisture resistant than the other materials.

It is also much easier to cut and attach than other materials such as MDF that must be cut with a large saw, while drywall can be cut with a utility knife.

Regular drywall has a very similar STC to plywood, OSB, or MDF. However, it is much cheaper and can be double layered for the same price or even less than a single layer of MDF.

For improved soundproofing, Quietrock drywall is the best way to go. Quietrock is sheetrock that has an improved STC rating while still having the benefits of gypsum board. If you’d like to learn about Quietrock vs double-layered drywall, read this article.

Drywall has a density of about 650 kg/m3.

Pros

- Not moisture absorbent

- Very cost-effective

- Sufficient STC rating

- Easy to work with

- Lighter than other materials of the same thickness

Cons

- Not very strong

- Can be difficult to finish and may require a professional

Price

The price of drywall depends on the thickness. Standard interior walls are usually covered with ½” drywall that goes for just under $12 per 4’X8’ sheet.

To increase the mass, and thus the soundproofing, I recommend using ⅝” type X drywall instead, which currently costs about $14 per sheet. This is the most cost-effective way to add mass to your interior walls.

Medium Density Fiberboard (MDF)

Medium Density Fiberboard (MDF) has an STC rating similar to drywall, although it has a higher density. However, it is much heavier and harder to work with.

Medium Density Fiberboard (MDF) has an STC rating similar to drywall, although it has a higher density. However, it is much heavier and harder to work with.

It is also held together with chemicals called VOCs that are released when you cut the board, making this much more difficult to deal with than drywall.

MDF is very strong, and if you need structural integrity to come from the panels you are using, then MDF may be the way to go.

MDF has a density of about 720 kg/m3, making it the densest option for soundproofing.

Pros

- Very Strong

- Sufficient STC levels

- Holds screws very well

- Very Smooth

- Easy to paint

Cons

- Very moisture absorptive

- Very heavy compared to same thickness drywall

- VOCs released when it is cut

- Expensive

Price

Similar to drywall, the cost of MDF will change with the thickness. A 4’X8’ sheet of MDF that is ½” thick is about $25. A ⅝” thick piece is $30. You can see how this would add up quickly if trying to cover walls in a double-layer of MDF!

OSB

OSB has similar soundproofing qualities as drywall or MDF. It is considerably cheaper than MDF and doesn’t absorb water as quickly. However, it holds on to moisture for a very long time when it does get wet, which is why it isn’t used in walls.

OSB has similar soundproofing qualities as drywall or MDF. It is considerably cheaper than MDF and doesn’t absorb water as quickly. However, it holds on to moisture for a very long time when it does get wet, which is why it isn’t used in walls.

While OSB is not as strong as MDF, it is stronger than sheetrock and could be used in applications where support is needed.

Unlike MDF, the adhesives used in OSB gas off naturally and will not release harmful VOCs when cut.

OSB has a density between 600-680 kg/m3.

Pros

- Strong

- Cheap

- Doesn’t absorb water fast

Cons

- Holds moisture for a long time

- Splinters

- Harder to work with than drywall

- Doesn’t look great/not a finished product

Price

OSB comes in slightly different thicknesses than the other materials we’ve discussed. A 7/16” thick 4’X8’ sheet of OSB costs only $9. However, this is thinner than the ½” drywall and will provide less soundproofing. A 15/32” sheet of OSB is just over $15, making it a bit more expensive than drywall of a similar thickness.

Plywood

Plywood is not nearly as dense as OSB or MDF, which means it is not quite as effective at blocking sound transmission. Many types of plywood are available that range in cost, finish, thickness, and kind of wood used.

Plywood is not nearly as dense as OSB or MDF, which means it is not quite as effective at blocking sound transmission. Many types of plywood are available that range in cost, finish, thickness, and kind of wood used.

Basic plywood sheathing used in construction has a density of 460-520 kg/m3. A hardwood, finish plywood sheet has a density of 620-680 kg/m3.

Pros

- Very Strong

- Not as susceptible to water damage

- Holds screws well

- Low to No VOCs

Cons

- Not very dense

- Splinters easily

- Hard to cut and work with

- Not the best soundproofing characteristics

- Expensive

Price

The price of plywood changes dramatically based on factors such as the type of wood used, the thickness, and the adhesive.

A 15/32” sheet of non-sanded sheathing plywood currently costs about $17, which is $2 more than a comparable sheet of OSB. The same size sheet in sanded plywood would cost $26, almost on par with the much denser MDF.

If you went with higher-end hardwood plywood, a single ½” sheet would cost about $46, making it the most expensive material on this list.

MDF vs Drywall for Soundproofing

Since MDF and drywall do have similar soundproofing capabilities, there are different applications where you might choose to use one material over the other.

On interior walls where a lot of coverage is necessary and a finished look must be achieved, drywall is the definite choice. Sheetrock is not absorbent; it finishes well and is easy to install. Because drywall is so much more cost-effective, you can also double-layer it for less than a single layer of MDF, giving you more density and improved sound reduction.

On the other hand, MDF is much stronger than drywall and can be used in situations where structural support is necessary. MDF would be the best choice for an inside unit such as a soundproof box for a compressor. MDF is also the go-to choice in applications such as home theatres and soundproof doors.

Plywood vs MDF for Soundproofing

While MDF is the go-to choice for many indoor soundproofing applications, there are situations where it is not optimal because of its water-absorbent properties.

Plywood would be the choice for sheathing your floor since non-sanded sheathing plywood is so much cheaper than MDF and is more resistant to moisture. To make the floor more soundproof, you could also add a second layer of plywood or a layer of insulation underneath.

Drywall vs OSB for Soundproofing

Both drywall and OSB have similar characteristics for soundproofing, and they are also priced very close to each other. So where would each one be the better option?

As discussed, drywall is the best choice for covering interior walls for many reasons. On the exterior walls, however, OSB is superior. It does not absorb moisture very quickly, and since it is so cost-effective, it can easily be double-layered for additional mass.

Because it is much stronger, OSB can provide the structural integrity necessary for sheathing external walls.

MDF vs OSB for Soundproofing

MDF and OSB are both very strong and have similar applications. Although MDF is denser, OSB is so much cheaper that in many applications you could double-layer it for the cost of a single layer of MDF. Of course, this would make your unit extremely heavy and is not recommended for something mobile.

OSB can also be used in any exterior applications, which MDF wouldn’t be a good choice for because of its water-absorbent properties. This makes OSB the best choice for an application such as a soundproof shed for air compressor.

How to Improve Noise Reduction

When you’re trying to make a space quieter by implementing soundproofing techniques, there are several ways you can improve the noise reduction. In this section, we will cover several different ways to improve your soundproofing.

Add Insulation

Insulation will provide absorption, one of our 4 principles of soundproofing. This will help kill the energy that the audio waves contain, stopping them from being transmitted.

Insulation can be added inside of interior walls to reduce noise transmission. It can also be added to floating floors to decrease vibrations further. Insulation can be used almost anywhere; there is an open space that sound transmission needs to be reduced.

There are many different types of insulation available. While standard fiberglass insulation does offer some dampening benefits, there are other options such as sound guard Rockwool that will provide even better soundproofing. For more information on different types of insulation and how they improve soundproofing, check out this article!

Increase Mass – Add More Material

This improvement relates to the soundproofing principle of mass. By using thicker material, or adding additional layers, we are creating more mass for the vibrations to attempt to move.

On interior walls, this would be achieved by double layering the drywall. On an exterior wall, you could achieve this by double layering OSB. If you were building a soundproof box for a compressor or vacuum, you could do this by building a box within a box, effectively creating two layers the sound must pass through.

Use Acoustic Drywall

Instead of doubling up on your drywall layers, you could try using acoustic drywall such as QuietRock. QuietRock alone can improve your STC rating by 15-20 points! For more information about this, check out my article on QuietRock here.

Resilient Channels and Sound Isolation Clips

Resilient channels are thin metal strips that attach to a wall, on top of the first layer of drywall. The second layer of drywall is then mounted to these strips, effectively decoupling the second layer of drywall from the rest of the wall.

Sound isolation clips work under a similar premise, except they attach directly to the studs. The rubber-backed clips are mounted to the studs, and then a metal channel is attached to the clips, running perpendicular to the wall studs. The drywall is then fastened to these metal channels.

Both resilient channels and sound isolation clips work by decoupling your wall from the outside and are very effective for improving soundproofing qualities.

Wall Studs

When you’re building walls that you want to be soundproof, opt for metal studs over wood studs. This change alone will result in a decrease in reduction by about 5db. Metal studs are not as rigid, and therefore they do not transmit the vibrations as easily as wood studs do.

For maximum soundproofing, you can stagger your studs, so that the inside and outside layers of the wall are each attached to their own set of studs. This is the decoupling principle of soundproofing in action.

Note: For another soundproofing wall option, please check out our article How to Build a Soundproof Room-Within-a-Room.

Use Mass Loaded Vinyl

Mass loaded vinyl or MLV is a rolled membrane that can be used to cover any surface to drastically reduce the sound that’s transmitted through. Because it is a very viscous material, it stops vibrations and is one of the most effective soundproofing materials available.

MLV is most effective when applied between layers, such as in between to sheets of drywall. MLV is very expensive, however and is best used when the price is not a factor.

Green Glue

Green glue is currently the most effective form of dampening available for soundproofing. It is applied between two panels, such as two sheets of drywall. It acts as a flexible, sound-absorbing layer that stops vibrations.

This is very easy to use and effective method. To use green glue to improve the soundproofing of your walls, you would simply apply it to the back of a piece of drywall, and then screw that drywall sheet to your existing wall. You now have a double-layered, dampened wall that even without any insulation inside, and without being double layered on the other side, will improve to an STC level of 43!

Conclusion

Depending on what you’re trying to soundproof, OSB, MDF, plywood, and drywall all offer soundproofing characteristics with their inherent advantages and drawbacks. After reading this article, hopefully, you understand which one best suits your particular needs!

If this article was helpful to you, feel free to share it so that it can reach other people who may also find it helpful. As always, comments and questions are appreciated and can be left in the comment section below.

That article was very helpful. Thank you. How about ventilation in sound proofed rooms?

Hi,

I’m going to build a sound dampening cabinet for a stationary compressor. I would use 2 layers of MDF, but I have some questions related to that:

1) Is rockwool (e.g. 5CM thick) a better solution than green glue between the MDF? I guess I cannot have both 🙂

2) For soundproofing windows you use 2 layers of glass with different thickness. Is that preferable with MDF as well?

Hello Eugene, my 22 cu. ft. Lg refrigerator is very noisy, and vibrates the wood floor, do you have any suggestions? Thank you Rick

Thank you for taking the time to improve the lives of others. Peace and “quiet” are valued by many!

This article was extremely helpful and has greatly informed my possible future purchases. Thank you very much!

Thank you for time and efforts to gather this valuable information collection ready to use for enthusiasts.

I’m going to make a home studio and comparison of currently used materials in the market was quite helpful for me

Thank you ?

Wow great article! Will guide me in my construction of garage turned music studio.

Exactly what I needed to know. I’ve read all this separately on other sites but it is great to have all this information in one place and re-validates my future purchase decision on sound proofing. Thanks!

very helpfull well layed out easy to understand. Thank you Eugene

Thank you for sharing this well researched and insightful article. I can now make more effective decisions at the big box store.

Regards,

Larry

Hi Larry,

Glad you found it useful.

Thanks,

Terry

Hey Larry, thanks for the article. Very informative. I’m in the process of getting an already treated sound studio but the work that was done there allows low frequency to pass through the material. Do You think that green glue and drywall could do the trick.

Thanks Eugene,

I’m planning to build (DIY) a small room for voice over recording. Your article is extremely good and very much appreciated.

Earl

Hi Earl,

Glad you liked it.

Terry

Thanks Eugene for sharing

I have a single leaf brick wall between the kitchen and the bedroom. A lot of kitchen noise is coming through to the bedroom. On the bedroom side of the brick wall, I am going to leave a 20mm gap, then build a 70×35 stud wall with sound batts, then clad on the inside of the bedroom with either 2 layers of drywall or one layer of thick mdf. What are your thoughts?

Thanks

Wayne

Hi Wayne,

Sounds like you have a good plan. 2 layers of 5/8″ drywall with Green Glue sandwiched between would be my choice. The Green Glue helps dissipate the noise. Another option is one layer of 5/8″ QuietRock with a sound dissipating polymer inside the sheets. You could also consider Mass Loaded Vinyl applied directly to the studs after insulating. MLV has an STC rating of 23. For more on QuietRock please see QuietRock vs Double Drywall: Which is Better for Soundproofing?

Terry

awesome layout of exactly how ,why, and comparable options.. i have a nice 6300 sq. ft.

1 story post and beam house in las vegas and i got really lucky the guy that built its brother was head of a demolition company. so he got most of the materials to build this custom for free.. the beams are poplar 8×12’s every 8 feet and the ceiling was the floor of the warehouse they tore down 3″ thick tongue and groove with 2 layers of 3″ roofing styrofoam then 3/4 ply, vapor, then torch down.. i just redid the roof instead of stripping it i did another layer of 1/2 in roof ply, screw down base, then torch.. every exterior wall is sheared outside with 3/4 , 2 bat of insulation 1 facing in from both sides then 1/2 ply then 1/2 in. sheetrock wall in the house. i built all the interior walls that go down the middle of the house seperating the gameroom from the main house with 2×6 , r24, 1/2 particle board on both sides the 1/2 in sheetrock on both sides. i can crank my stereo just over 100 decibles and it is barely a whisper at the kids rooms down the other end.. but i am getting ready to make a recording room out of my mudroom 8×16 so i may add a layer of 1/2 particle covered with green glue or something similar then another 1/2 of rock with a 1/2 those 12×12 acoustic panels…. whats with all the particle board.. i bought 400 sheets that were used 1 weekend for a roller durby from a casino 2$ a sheet like years ago and i still have 60 left….lol

i did have 1 question.. how would r tec 1 1/2 rigid foam 4×8 panels be as far as noise canceling.. you could green glue and stick it to the existing wAll then green glue the other side and screw your sheet rock to it…

Hi Dave,

Rigid foam is not great for noise cancelling. Either 5/8″ standard drywall or QuietRock with Green Glue sandwiched between them are better options. Gives you mass and sound damping. I am also not certain how Green Glue reacts with rigid foam. Might just burn its way into it and you will not get any benefit from it.

Terry

Thank you, your time spent on your research is much appreciated for a busy mum like me. Reading your artical has saved me a lot of time, I now know the best way forward on ceiling choice for my new kitchen and hallway.

Hi Vicky,

Good to know it helped.

Terry

Thanks for your great articles. I am building a 33’ x 54’ indoor gym which is an add on to existing house. 33’ side is using exterior wall of existing house. The 54’ gym wall is an interior 2 x 6 wall (structural wall). The gym height is 20’. On the other side of 54’ wall is a new two story living area. Hoping to keep noise from gym out of existing house and out of new two story addition.

Will be building a second 2 x 6 sound wall on gym side of 54’ long structural wall with 2” gap between the 2 walls. Will use rock wool insulation The sound wall will have MDF or plywood painted as finish wall on gym side. Would it be better to put drywall under MDF, and would green glue help if applied between MDF and drywall or would it be better to double up drywall with green glue on the gym side of structural wall?

The 33’ wall is attached to existing house, that has a 2 x 6 existing wall that is insulated and with 7/16 OSB. Was considering adding mass loaded vinyl sound proofing barrier to OSB, then layer of drywall and then add the finished MDF. Would it help to add green glue between drywall and MDF? Other suggestions. Thanks.

Hi Jim,

I might be tempted to hang 1 lb. Mass Loaded Vinyl on the gym side studs instead of the drywall/MDF combination. I would also go ahead and use MLV on the 33′ wall. I would also use 3/4 Good 1 Side plywood instead of MDF if there is any chance of moisture getting on it. I know it is slightly better for soundproofing than plywood. But get a few drops of water on it and it starts swelling. Also, using plywood allows you to attach anything anywhere. MDF holds a little better than drywall, but only for shear issues. I do not trust it to hold up shelving where there could be quite a bit of torque. Just a personal preference.

Terry

Hello Terry,

Great article, thank you. I’m trying to turn a (tiny!) closet in the new house we are renting into a booth for voiceover recording. Thus far, I have fully covered the interior (including floor) with a single layer of MLV, tacking it to the drywall. My intention was to next cover that with 3/4 plywood; on each of the three interior walls at about head-height, there is a single 1″ board screwed to the studs, the former supports of a shelf I removed. I would attach the plywood panels to these, thus creating a roughly 1″ overall gap between the MLV layer and the plywood layer, save for the connecting surface of those boards (which themselves have been covered in MLV). For the floor, I plan to put some 1″ spacers atop the MLV, then layer a piece of plywood on top of that, creating a poor man’s floating floor. Just running this by you to see what you think, and if you you have any feedback/recommendations.

Oh, I should also add that this closet (really the only space I could make this work in the new place, until I can afford to buy or build better) is bordered by two high-traffic and noise-conducting spaces in the house: a closet and two flights of stairs. The closet floor is actually just above the sloped ceiling of the lower flight, down to the basement (home of 65db heat pumps, naturally). So, bit of an uphill noise battle, currently…

Thanks in advance!

Mike

Hi Mike,

Sounds like you are well on your way. About the only thing I would suggest is BXI Anti Vibration Pads and 1″ plywood for your floating floor. Pads for better isolation and thick plywood to eliminate sags and squeaks. Tongue and groove if you can get it. You might also want to look at our article How to Soundproof a Closet.

Terry

I hate to bother with additional questions, but I can’t find a better resource! My 1850 farmhouse is on a highway and after another sleepless night, I got up and tore an exterior wall apart. Oops. I took out the 3/8 rock and removed the mouse infested r11. I used acoustic caulk to fill all the gaps and installed the old rock against the clapboards. Now my poor planning really comes into play. My question is::: Is it worth padding out the wall to 2×6 to fit thicker ROXUL? Or just double up on 5/8 drywall w acoustic caulk? The attic (access and open bays into my room) is a source of noise despite 10″ cellulose and r30 glass…would laying down a sheet of MLV up there help? THANKS for your helpful and comprehensive articles.

Hi Val,

I can sympathize with “OOPS”. I sometimes have “Ready, Shoot, Aim” down to an art form.

If the cavities are relatively unimpeded, I would give some thought to blowing loose fill cellulose in them. Cut small holes at the top of each cavity, drop the hose to the bottom, turn the air on the machine down, and retract the hose slowly–filling the entire cavity. Patch the hole. Then add another layer of 5/8″ drywall with Green Glue sandwiched between. You can usually rent the machine from the place you buy the product. I know that Home Depot offers that option. Or you can get an insulation contractor in to do the work.

You can build the wall out and use thicker Roxul. Or you can build the wall out and spray wet cellulose which sticks to the wall, then install 5/8″ drywall or 5/8″ QuietRock.

I think MLV in the attic over all that insulation would be a waste. Very difficult to achieve good tight fits around trusses, rafters, wiring, plumbing, and vent stacks. Check your attic access for insulation and weatherstripping. People often forget to build a box that will hold insulation on the top of the access panel. Install a good thick soft rubber weatherstrip around the access. It seems to me that all of that cellulose and fiberglass should keep the attic quiet.

Terry

I never have to look at another video or read another article!

Concise

Thorough

I wish you wrong every article, I would have more time and a better understanding!

Thanks

Hi Art,

Glad you liked it. Thanks for the kind words.

Terry

Thanks for the article. Very informative. I’m in the process of getting a relatively treated sound studio but the work that was done there allows low frequency to pass through the structural material. Do You think that green glue and drywall could do the trick?

Hi Nikos,

Bass is always the enemy. Green Glue and 5/8″ drywall will help a lot. Make sure you have bass traps in all the corners–floor and ceiling. You might want to check out our article How to Keep Bass From Going Through Walls.

Terry

hi am trying to build a wall adjacent/attached to the existing wall of my bedroom.

8′ tall, 10′ large.

to stop air condoning and vibration from my neighbour

I have like about 2 and 5/8 ” or maybe more as a space for the thickness of this wall.

-what insulation you suggest? are the foam panel of Home Depot ok?

-was thinking to attach on floor and ceiling metal frames, put insulation between them, then add some plywood panels

I know you advice drywall..but doesnt look so easy to put screws in, doesnt seem solid..makes lot of dust when cut…

– I even though to add a brick wall…

Thank you for the article! How do all of these materials compare when it comes to IIC? I ask because I am looking to put materials into a ceiling assembly. I will eventually be able to make additional modifications to the floor above when I remodel the floors also – probably 5 years from now.

Thank you for the awesome article. Loved the comparison. I agree MDF is more expensive than dry wall. Not sure if I can paint over it as well. I am building a very small recording studio. 1.4m X 2m at a height of 2.6m. It is basically a room within a room in my current house. The outside wall are double wall already but there is a big window facing my neighbors house. It is more to cut out the noise from barking dogs. I was going to go with drywall outside and inside and use a insertion rubber in the middle. I cant find MLV in my country Namibia (Africa). I am in the capital. I was thinking of using the vehicles noise cancellation mats. add Insulation as well. When my neighbors dogs bark I get a 60db reading. Will that be effective? I want to reduce that to at least a 10-20db.

Hello

Im planning to build a DIY Vocal Booth to practice singing in so that i dont disturb my neighbours. What are the most efficient materials i can use to create the best soundproofing? My budget is $1000. This is my plan so far:

Wood frame, outer drywall panel, rockwool insulation inside, then another layer of some foam insulation (styrofoam?) + OSB glued together as inner panel. Then add acoustic panels for the inside of the booth as acoustic treatment and extra sound absorption.

If i understand correctly the materials in this construction provides the following:

Mass: Outer layer of drywall and inner layer of OSB.

Absorption: rockwool insulation, or maybe cheaper fibreglass is enough?

Dampening: a layer of foam insulation will provide dampening (would green glue be

better?)

Decoupling: im not sure how to achieve this in an easy way

Some questions i have:

– How thick should each layer of material be? E.g. the drywall

– Maybe it would be worth to have multiple layers of drywall instead of one thick layer of OSB to reduce costs?

– Would it be worth to add a layer of green glue or a layer of mass loaded vinyl? I heard those are quite expensive though, and it might be overkill.

– Instead of rockwool insulation i could use some cheaper fibreglass insulation?

I wonder if there are some other cheaper materials i can use to achieve equal or better amount of soundproofing for less cost. Or perhaps spend a bit more money on better materials for a significant jump in soundproofing. Or just make use of smarter construction design to increase soundproofing.