It’s nice to sit and work or relax with the window open, but when outside noises intrude, shutting the window and muting them is great. Don’t you wish you could do the same with noise inside your home, apartment, or office? There are many soundproofing materials and products available that can be used during construction, and post-construction, to improve the sound quality within your living and working space.

Whether you’re a DIYer, a contractor, architect, or you just want to know what there is out there that can help so you can have an informed thought on the subject, this is the information you need. All of these products and processes will work for a home or business owner, and some can be used if you rent – use the information with your Super to get permission. Everyone should be able to have a quiet place to relax, sleep, or work.

Main Principles of Soundproofing

When we use the term soundproofing, we are not talking about canceling all sound. Most of us would not be happy in a truly soundproof room.

The term soundproofing means to decrease or control sound vibration movement into or out of a space, thus improving sound quality within that space. Sound frequency is also a factor; low bass sounds are much more difficult to block than higher frequencies.

There are four main principles or components to soundproofing. Used independently of each other, they will impact some sound; together, they will have the greatest impact on controlling sound.

Adding Mass

Noise travels as a sound wave vibration and can penetrate anything it can vibrate through. The heavier something is, the more difficult it is to move.

Adding mass or density will decrease the amount of soundwave penetration. Unfortunately, it can take a lot of mass to have much impact.

Mechanical Decoupling (Mechanical Isolation)

Mechanical sound is noise that travels through the connected structural members of a building. Whether impact vibration caused by heals on a floor, a ball bouncing on a wall, or water in a pipe causing vibration as it travels through your home, it is difficult to control.

When you decouple or break the mechanical path, you isolate the soundwave movement. However, decoupling can also make some low-frequency sound increase while significantly quieting high frequencies.

Absorption

Installing insulation between the studs or joists will help absorb mid to high-frequency soundwaves. It won’t impact low frequencies or those that travel through the studs or other structural materials. Absorption is most effective when used with the other three principles.

Damping

Sound waves are vibrations, so materials that stop or decrease vibrations will also improve sound transmission loss. Viscoelastic materials like Green Glue or mass loaded vinyl (MLV) provide a flexible layer that can separate materials and prevent vibrational movement, and reduce sound movement.

What are Soundproofing Materials and How Do They Work?

Soundproofing is about controlling the movement of noise into or out of your room, home, or office. We can’t stop all of it; however, we can minimize most of it.

Sound is a vibration and a form of energy that can travel great distances unless interrupted or trapped. Soundproofing materials are substances that independently or working together, reflects, absorbs, or diffuses sound energy.

Low frequencies are the most difficult to control. High and low-frequency waves travel at the same speed, but they aren’t generated as frequently.

The crests of the frequency waves are closer together for higher tones, or repeat more often at the same time, and further apart for lower tones. The closer the crests, the easier they are to trap. Low bass sounds or tones have a greater distance between crests, so they are harder to block.

Soundproofing materials can reflect sound and prevent it from continuing on its path. However, this can also be problematic as it creates an echo.

Absorbing the sound converts the sound energy into heat. The sound wave vibrates into a material that has air spaces inside, the wave is trapped, and the energy becomes heat which dissipates into or out of the room.

Materials that diffuse sound waves treat or condition sound echo or reverberation. They improve the quality of sound within a room.

There is not one definitive material that does everything. Products and construction techniques work together to optimize sound control.

Whether it is double-wall construction with resilient channels, clips, insulation, MLV, and Green Glue, or a standard insulated wall with curtains or a dense moving blanket hung on it, the goal is to absorb, reflect, and diffuse enough sound waves to control the amount entering or exiting.

Understanding Sound Ratings

Different products, materials, or a combination of materials have been tested by manufacturers or independent labs for their sound control and given ratings. The ratings help consumers and industry professionals when selecting soundproofing materials.

However, it’s important to understand what the terms mean and to realize laboratory results aren’t what you may get at home or elsewhere. Additionally, most sound ratings avoid the lower frequencies.

STC

The Sound Transmission Class (STC) is a numerical value given to building materials or assemblies and other materials based on how well they control the transmission loss (TL) in decibels (dB). The STC rating is established by tests involving 16 standard frequencies between 125 Hz and 4,000 Hz.

The results are graphed and compared against an industry fixed curve, and the rate is based on the improvements; the higher the STC value, the better the results you can expect.

NRC

The Noise Reduction Coefficient (NRC) is a numerical value between 0 and 1.0 and rounded to 0.05 of the nearest number. It identifies how well a material absorbs or reflects soundwaves based on 4 common frequency ranges in speech – 250 dB, 500 dB, 1,000 dB, and 2,000 dB. The greater the value, the better it controls sound.

IIC

Impact Insulation Class (IIC) rates how well a material or assembly absorbs impact sound. Impact vibrational noise can travel through connected parts of a structure unless there is a resilient material that absorbs or prevents its transmission.

A test using steel hammers that mimic footfalls strike the test floor generating frequencies between 125 and 4,000 Hz. The results are graphed and compared to a reference which determines how well a material or assembly resists the transmission of impact vibration. A higher value is desirable.

OITC

The Outdoor-Indoor Transmission Class (OITC) rates materials from 80 Hz instead of 125 Hz as the STC does, so it addresses the lower sounds made by trucks, planes, trains, and lawnmowers. It offers a better indicator for sound control when selecting windows or exterior doors. The higher the rating, the more it controls noise movement.

The ratings that are of most value when selecting materials or partition assemblies for a structure are the STC, IIC, and the OITC. It is important to understand that a product’s rating isn’t added directly to that of another; it is how they are combined and work together.

For example, adding a door with an STC of 55 to an uninsulated wall rated STC 33 isn’t going to improve the wall rating, or solve the noise transmission problem.

Guidelines for new construction and renovations are supposed to adhere to building code minimums. Noise concerns in older buildings can be addressed by room or apartment as improvements are made or required.

The Unified Building Code (UBC) and International Building Code (IBC) recommend Lab STC ratings of 50 for wall and ceiling partitions, although field test results may be 5 points lower. An IIC of 50 is acceptable for most building codes too, although you may still hear some heal impact with an IIC of 70.

Types of Soundproofing Materials and Products

There are many types of soundproofing materials and different terms applied to them. A brief description of the terms and some examples of materials are always helpful.

Sound Absorbing

Sound absorbing materials trap sound vibration within the airspace and reduce the intensity of the sound by converting some of the sound energy into heat. They help to control echo and reverberation too.

Heavy plush curtains, moving blankets, insulation, and acoustic wall panels reduce sound movement by trapping or absorbing sound waves within the folds or layers.

Sound Insulation

Most household insulations not only decrease the movement of heat and cold but also the movement of soundwaves. Dense insulation has a greater ability to trap sound vibrations and convert them to heat, so the better its acoustic performance; usually.

Spray foam insulations are the exception; they act as a coupling agent between wall members, making it easier for sound to travel through. Loose-fill and batten fiberglass, stone wool, cellulose, cotton, and wool insulations are good sound-absorbing materials.

Acoustic Decoupling

Decoupling is a method of separating layers, often in construction that prevents sound vibrations from traveling from layer to layer. Resilient clips and channels help decouple drywall from framing, thus reducing sound transmission.

Acoustic caulking is used to fill in holes or gaps, and to separate wall partitions from each other, and the ceiling and floor. Acoustic drywall, double-wall construction, sound clips, damping products are other methods of acoustic decoupling.

Sound Dampening and Deadening

Products that damp sound prevent or reduce vibrational movement, which inhibits noise movement through it. Viscoelastic materials like Green Glue, putty pads, rubber mats, high impact foam, or mass loaded vinyl (MLV) are often used to damp sound.

Sound blocking or deadening materials are dense materials that block sound movement. MDF, heavy felt, and MLV are three products that block or deaden sound – one is rigid, the other two are flexible.

Soundproofing Barriers

Soundproof barriers are made of layers of fiberglass, foam or vinyl and are used to permanently or temporarily block, deflect, or damp soundwave vibration and energy. They can be rigid or flexible and often have self-adhesive options for easy application.

The barriers can be used to wrap pipes, ducts, over drywall, even in cars, planes, and boats. MLV, fiberglass blankets, polyurethane foam and cotton composite blankets are some examples available.

Soundproof Underlayment

Hardwood, stone or ceramic tile, and even vinyl flooring can cause a headache to anyone in a room near or below due to impact or footfall noise. Different types of underlay can be used under the flooring to deaden the sound and prevent its transmission.

Cork, acoustic foam, and polyethylene foam are three possibilities and can range from 1/8” to 1/4″ thick. It is the density or weight that is needed, not the thickness though, and felt underlay is between 3 and 4 times denser or heavier than most.

Door Seals and Sweeps

Sealing the perimeter of a door is a quick way to reduce sound movement in or out – provided the door isn’t hollow core. Self-sticking weather stripping applied to the door jamb, so it compresses when the door is shut and latched is an effective way to block sound.

However, noise can bounce under the door, so adding a door sweep or automatic sweep will solve that problem. Door sweeps are more effective on smooth floors or those with a threshold.

Soundproofing Installation/Construction Materials

Soundproofing is the elimination, reduction, or blocking of annoying or disruptive sounds. Distance is one way to reduce noise, the further you are away from the sound source, the less intrusive it is. Hard to do in most places though. However, moving your refrigerator 2-inches away from the wall will decrease vibrational transfer through connected building materials.

Adding absorption materials like an insulated blanket hung behind the refrigerator will absorb and mute some of the sound vibrations too. The addition of rubber vibration isolator mats under the fridge or other appliances will also damp the sound movement too. So distance, absorption, and damping are ways soundproofing materials can be applied into any home or office.

When selecting materials to soundproof a new build or an existing structure, you need to understand the properties that will make them a good soundproofing material. The 4 principles – absorbing, damping, decoupling, or adding mass – provide that information.

The density of a material is important whether it is insulation for absorbing sound, MDF to block it or MLV to damp it. The greater the density means more mass, the harder it is for sound to penetrate, and the sound is blocked.

Resistance to sound waves, or flow resistivity, measures the ease with which sound can move through a material.

While air and water may move through a porous material, sound can become trapped in the pores and converted to heat, thus absorbing the noise vibration. The porosity of a material is important in sound controlling materials.

The cellular structure of a material is important too. Cell size and shape influence the movement of different frequencies through a material. Open and closed-cell products are also factors for consideration and affect the density, porosity, and flow resistivity.

Sound waves travel in a straight line until they meet a material that deflects, reflects, or absorbs them. The cellular structure and porosity of the material can create a tortuous, or windy, twisted path for sound waves to travel through. The more tortuous the path the sound wave encounters, the greater the transmission loss, so the greater the tortuosity of a material, the better.

Best 32 Soundproofing Materials and Products [Reviews]

Soundproofing Insulation

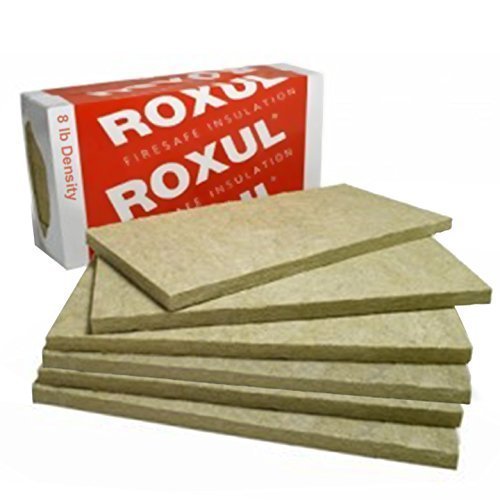

Acoustic Mineral Wool Insulation

Mineral or stone wool is also called Rockwool or Roxul and is made from molten slag or stone that is spun into fiber. It won’t combust and doesn’t absorb moisture, so it is mold or mildew resistant. The multi-directional fibers create a rigid, dense yet porous batten or panel that works well to prevent the movement of sound, heat or cold through it.

Mineral or stone wool is also called Rockwool or Roxul and is made from molten slag or stone that is spun into fiber. It won’t combust and doesn’t absorb moisture, so it is mold or mildew resistant. The multi-directional fibers create a rigid, dense yet porous batten or panel that works well to prevent the movement of sound, heat or cold through it.

The battens and panels are rigid, so they don’t slump like fiberglass, which can create gaps in your sound and thermal barrier.

Stone wool is easy to work with, cuts with a utility knife, and fits snug between studs. It doesn’t have the airborne particles that irritate like fiberglass, which cause health concerns either. However, it is always a good practice to wear gloves, eye protection, and a dust mask when working with any insulation.

Rockwool Acoustic 80 has a density of 8 lb/ft³, an NRC rating of 1.0, and comes in 2’x4’ panels that are 2-inches thick. The density and NRC value make it ideal for absorbing low, mid, and upper-frequency sound.The sheets can be used in walls and ceilings to decrease sound movement. It is also perfect for bass traps and acoustic panels suspended on walls or ceilings to control reverberation, echo, and slap.

For sound control insulation, Rockwool 80 is my preference. It has a high NRC, is easy to work with, and less expensive than equivalent fiberglass products.

NRC Rating: 1.0

Best Uses: Mineral wool works great as an acoustic or thermal barrier within walls or ceilings, and is ideal for acoustic panels or bass traps.

Pros

- Excellent acoustic absorption and thermal barrier

- Inexpensive and easy to use

- High fire rating

- Resistant to moisture, mold, and mildew

Cons

- Can be difficult to find

Soundproof Fiberglass Insulation (Owens Corning 703)

Fiberglass is made of molten glass that is spun into wool. It has tiny shards of glass embedded in it too. The loose wool-like material traps air and sound, making it a good thermal and sound barrier.

Fiberglass is made of molten glass that is spun into wool. It has tiny shards of glass embedded in it too. The loose wool-like material traps air and sound, making it a good thermal and sound barrier.

The battens are not rigid and can slump, causing gaps in the thermal and sound barrier over time. It also absorbs moisture, reducing its efficiencies, and allowing the growth of mold and mildew. It is not as dense as stone wool insulation of comparable thicknesses, so doesn’t have equivalent thermal or audio ratings.

Fiberglass battens can be cut with a utility knife. Unfortunately, that compresses the fibers which don’t spring back, thus decreasing its thermal and acoustic abilities. Fiberglass has irritating fibers that become airborne and cause health issues. Always wear gloves, safety glasses, and a dust mask when handling fiberglass battens or panels.

Owen-Corning 703 Acoustic Insulation is similar to Rockwool 80 for an apple to apple comparison. It is a 2’x4’ 2-inch thick rigid panel with a density of 3 lb/ft³. There are several different products within the OC 703 line, and the NRC varies from 0.75 to 1.00, depending on which one you look at, as does the price. 703 works well in walls and ceilings, and can also be used for acoustic panels or bass traps.However, ensure that it is wrapped, so particles don’t become airborne.

STC (or NRC) Rating: 0.75 to 1.0

Best Uses: fiberglass works well for thermal and acoustic control within walls and ceilings. Rigid panels like OC 703 also perform well at controlling echo and reverberation when used in bass traps and acoustic panels.

Pros

- Good thermal and acoustic properties

- Easy to use

- Good fire rating

Cons

- Battens slump and compress

- Susceptible to mold and mildew growth

For more information on each type of insulation, as well as a comparison between products, check out my post Soundproofing Insulation for Noise Reduction.

Sound Absorbing Materials

Acoustic Curtains

Acoustic curtains don’t have to cost an arm and a leg, nor do you have to purchase them at a specialty store. Fabric curtains that are thick, soft polyester velour or velveteen type material are great.

Acoustic curtains don’t have to cost an arm and a leg, nor do you have to purchase them at a specialty store. Fabric curtains that are thick, soft polyester velour or velveteen type material are great.

They are available in a multitude of colors and are also easy to clean. The panels reduce and absorb sound reflection, softening the sound.

The thicker or heavier the fabric, the more folds or pleats, the better it will trap and absorb sound reflection. Hanging the curtains six to twelve inches away from the wall also helps create a dead air space, improving sound control across all frequency ranges.

The curtains can be hung above windows, doors, or on empty walls to control sound within a room, or coming through from outside the room.

Blackout or thermal curtains are my preference. They offer more bang for your buck and are multi-purpose. The curtain panels often have layers of different fabrics that treat different noises, controlling noise movement when closed.

The window side may also have a vinyl-like material that reflects sound from outside. Additionally, the thermal rating means it decreases solar heat and UV penetration in the summer, as well as heat loss in the winter, which improves energy costs.

Curtains that are rated soundproof are heavy, at least 32 ounces per square foot. Some have a layer of insulation quilted between fabric, and others have MLV layered in. The MLV can increase the weight by half a pound up to 2.5 pounds per square foot, making for a very heavy curtain and increasing the STC rate between 25 and 33 points.

STC Rating: 25 to 33

Best Uses: Use the curtains to across windows, doors, or on walls to control reverberation, absorb sound waves, and to soften noise entering or leaving a room.

Pros

- Softens and absorbs low through high frequencies.

- Easy to install.

- Multiple color options.

- Easy to clean.

- Inexpensive.

Cons

- Insulated of MLV curtains are expensive.

- Only effective when drawn or closed.

Moving Blankets

Moving blankets are an inexpensive option for controlling sound. The blankets are thick and have cotton or polyester batten quilting between fabric layers. The blankets absorb vibration, sound, reverberation, and dampen sound. They are used to protect furniture from movement when moving, and also to reduce machinery sounds.

Moving blankets are an inexpensive option for controlling sound. The blankets are thick and have cotton or polyester batten quilting between fabric layers. The blankets absorb vibration, sound, reverberation, and dampen sound. They are used to protect furniture from movement when moving, and also to reduce machinery sounds.

The heavy quilted blankets trap and deaden low frequencies, reducing reverberation, and bounce. The blankets are easy to hang and can improve the quality of sound in bedrooms, home theaters, laundry, or utility rooms.

Note: For more information on moving blankets, please see our article Soundproof Blankets for Windows.

Best uses

Moving blankets work well to soften noise within rooms, or the movement of sound through walls. They are an easy addition to walls or as a cover for doors or windows.

STC & NRC Rating: varies depending on fabric weight, thickness, and application.

Pros

- Help control low-frequency sound.

- Inexpensive.

- Easy to hang.

- A good option for apartment dwellers.

Cons

- Color selection is very limited.

- Can have an odor initially.

Sound Absorbing (Acoustic) Fabrics

There are a variety of sound-absorbing fabrics, or fabrics that absorb sound; there is a difference, especially in the cost. Materials with an STC or NRC rating identify how effective they control sound. Some fabrics have both ratings, others one or the other depending on which test the manufacturer uses.

There are a variety of sound-absorbing fabrics, or fabrics that absorb sound; there is a difference, especially in the cost. Materials with an STC or NRC rating identify how effective they control sound. Some fabrics have both ratings, others one or the other depending on which test the manufacturer uses.

Frequencies between 125 Hz and 4,000 Hz are used to test the effectiveness of different materials. If you can get a copy of the results for the different frequencies, the information can be useful to determine if it will help with high or low range sounds. Remember, the overall rating is the average for NRC and the graphed improvement for STC.

The fabrics can be used to cover acoustic traps, panels, and diffusers, even furniture too. It can also be made into curtains to absorb or trap frequency waves. If you’re looking for more information, I wrote an article about the best sound absorbing fabrics which you can find here.

STC & NRC Rating: The ratings depend upon the material used and the application.

Best uses

Acoustic fabrics are excellent for wrapping wall or ceiling panels that control sound, helping to reduce reverberation, slap, and echo.

Pros

- Available in different colors and textures.

- Fibers and fabrics absorb soundwaves of different frequencies.

- Easy to use.

- Many are fire rated too.

- Inexpensive.

Cons

- Requires some skills and tools

- Can be expensive.

Acoustic Foam Panels / Acoustic Wedges

Acoustic foam panels come in a selection of colors and sizes. The panels can be oriented to address soundwaves moving in different directions, thus controlling reflection, reverberation, and damping noise. The surface of the foam may be beveled, ridged with hexagonal hills and valleys, wedges, or other shapes that can trap and absorb sound.

Acoustic foam panels come in a selection of colors and sizes. The panels can be oriented to address soundwaves moving in different directions, thus controlling reflection, reverberation, and damping noise. The surface of the foam may be beveled, ridged with hexagonal hills and valleys, wedges, or other shapes that can trap and absorb sound.

Foam panels work well to control mid to high-range frequencies and can be attached to walls, ceilings, and even doors using adhesive strips or spray adhesive. The panels help mute conversation sound, outdoor noises, and can be used in homes, offices, and schools.

The thicker and denser the foam, the better it works. The panels create a soft surface to absorb frequency waves instead of reflecting them.

Noise is deadened, and echo controlled, improving the sound quality in media rooms. The panels can also be used in apartments to improve sound control, without damaging the walls.

STC & NRC Rating: Foam panels may or may not be rated. The profile, thickness, and density of the panels, as well as placement, impact their effectiveness.

Best uses

Acoustic foam panels work well as corner traps, acoustic wall panels, or on the ceiling to decrease reverberation and echo.

Pros

- Control mid to high-frequency sound.

- Inexpensive.

- Easy to add to home, apartment, or office.

- Foam can improve the sound quality in a room.

- Helps decrease sound movement through walls.

Cons

- Can be cheaply made – you get what you pay for.

- The adhesive doesn’t hold well.

- No good for low frequencies.

Acoustic Panels (ATS Acoustics)

Acoustic panels help address the reverberation and bounce back produced by media systems and even conversations. They absorb mid to high range noise, and softening the feedback and making it cleaner. Acoustic foam panels work best from 500 Hz upwards, while stone wool or fiberglass panels are good from around 100 Hz and up.

Acoustic panels help address the reverberation and bounce back produced by media systems and even conversations. They absorb mid to high range noise, and softening the feedback and making it cleaner. Acoustic foam panels work best from 500 Hz upwards, while stone wool or fiberglass panels are good from around 100 Hz and up.

The panels can be freestanding, mounted to walls, and suspended from the ceiling to provide multi-directional control. To make the panels appear less obtrusive, they can be covered with colored fabric, photo prints, or cloth art images.

Some panels have a perforated wood cover that controls feedback and sound. For more information about acoustic panels, check out my article here.

NRC Rating: 1.0

Best uses

Acoustic panels work best when hung on the wall opposite speakers or sound-producing devices. If placed behind where listeners stand or sit, the panels clean up the return sound, improving the listening enjoyment. The panels are ideal for studios, media rooms, indoor recreation spaces, auditoriums, offices, and living rooms.

Pros

- Good sound conditioning.

- Easy to install.

- Multi positioning use.

- Inexpensive.

- Decorative applications.

Cons

- Fabric can fade or change color.

- Some have California Proposition 65 warnings.

Bass Traps

Bass traps help control the low-frequency reverberation, echo, and ringing caused by sound waves reflecting off hard, flat surfaces. The thicker and denser the material, the more sound it can control.

Bass traps help control the low-frequency reverberation, echo, and ringing caused by sound waves reflecting off hard, flat surfaces. The thicker and denser the material, the more sound it can control.

The optimal thickness is 6-inches and allows less air movement and thus better sound control. The sound waves are trapped within the fibers and converted to heat energy, which disperses, cleaning up the noise.

Most bass traps are triangular based prisms and fit into corners where walls meet, or the ceiling meets the walls. However, they can also be rectangular instead and placed across a corner to do the same task.

Much depends on the absorbing material used within the trap, and if the person positioning the trap chooses to have a more versatile or mobile use. Rectangular shaped conditioners can also be placed flat against the wall to condition sound instead of just in the corners.

Traps can be made of wood frames with insulating material inside and a fabric covering. Alternatively, they can be soft foam shaped or sculpted to capture soundwaves. The denser the foam, the better it performs.

Note: For other information on controlling bass frequencies please see our article How to Keep Bass From Going Through Walls and How to Block Out Low Frequency Noise.

NRC Rating: Depends on the material used – stone wool has an NRC of 1.0, fiberglass is 1.0, and high-density foam traps range from 0.45 to 1.20. The cost of traps that are rated can be significantly greater than unrated traps. Check out my post about plans and ideas for DIY bass traps.

Best uses

Bass traps are ideal for use in studios, media rooms, auditoriums, and music rooms. They absorb and treat sound crush in the corners of walls and at the ceiling to improve sound quality.

Pros

- Improves sound quality within a room.

- Different colors are available to enhance the décor.

- Easy to use.

- Versatile arrangements are possible.

Cons

- Traps don’t prevent sound transmission into or out of a room.

- Can be expensive to do a room.

Acoustic Decoupling

Resilient Channel

Resilient channels are perforated metal strips that attach to wall studs or existing drywall; a sheet of drywall is then fastened to the channel. The channels separate or decouple the layers of the wall, decreasing sound transmission in or out of a room. It is common to use resilient products in conjunction with other soundproofing products.

Resilient channels are perforated metal strips that attach to wall studs or existing drywall; a sheet of drywall is then fastened to the channel. The channels separate or decouple the layers of the wall, decreasing sound transmission in or out of a room. It is common to use resilient products in conjunction with other soundproofing products.

The thickness of the drywall, insulating material used between the studs, use of acoustic caulking, MLV, and viscoelastic material all contribute to the effectiveness of the resilient channels. The channels help to break or isolate the path sound waves follow as they vibrate through connected construction materials.

The installation usually occurs during new construction or renovations where it is important to decrease the movement of sound.

STC Rating: The STC is based on the construction method and materials used with the Resilient Channels. They can improve a wall rating from 33 upwards of 60 or higher.

Best uses

Resilient Channels are best used to decouple walls in rooms where sound control is most desirable – sound studios, media rooms, or where privacy is desired.

Pros

- Channels decrease sound movement in or out of a room.

- Can be used over existing drywall to improve sound control.

- Easy to cut and use.

- They help prevent impact noise movement.

Cons

- Resilient Channels are expensive.

- Are one part of a multi-component soundproofing process.

- Decreases floor and ceiling space.

Resilient Sound Clips

Resilient Sound Clips help to decouple wall or ceiling construction and can be used on concrete, wood or steel framing. The clips help reduce low-frequency, as well as mid through high-frequency noise. If used for ceiling construction, they control impact transfer between floors too.

Resilient Sound Clips help to decouple wall or ceiling construction and can be used on concrete, wood or steel framing. The clips help reduce low-frequency, as well as mid through high-frequency noise. If used for ceiling construction, they control impact transfer between floors too.

The clips can be used in conjunction with resilient hat channels to decouple the drywall from the framing or joists. Decoupling greatly decreases the movement of sound into or out of a room, making it easier to enjoy your quiet space.

Resilient clips are one component of the construction process and are frequently used in new construction or renovations where sound control is important.

STC Rating: The clips can improve the STC rating by 15 points, depending on the construction materials and techniques applied.

Best uses

Resilient clips are best used when you need to decouple a wall or ceiling to decrease sound transfer or impact noise.

Pros

- Decouple wall or ceiling members.

- Clips improve all frequency sound control.

- Easy to use and install.

- They decrease impact noise through connected structural members.

Cons

- Expensive.

- Makes walls or ceilings thicker.

Joist Gasket Tape

Joist gasket tape fastens to joists or studs to eliminate squeaks and impact transmission. It is a low-density, closed-cell PVC foam that helps control vibrational sound transfer. The adhesive is only on one side, making it easy to stick to joists or studs. Additionally, the gasket helps reduce heat or cold transfer between structural members, improving utility costs.

Joist gasket tape fastens to joists or studs to eliminate squeaks and impact transmission. It is a low-density, closed-cell PVC foam that helps control vibrational sound transfer. The adhesive is only on one side, making it easy to stick to joists or studs. Additionally, the gasket helps reduce heat or cold transfer between structural members, improving utility costs.

The durable gasket tape is manufactured by Green Glue and is available in different widths. The 1-7/16” is perfect for single dimension lumber joists or studs, and steel studs. The tape also comes in 2-1/4” and 3” widths for double joists or studs, or those that are engineered.

STC Rating: The joist gasket tape isn’t rated since it would be part of the whole partition rating.

Best uses

Joist gasket tape is ideal for use between joists and subfloor, or between studs and drywall. It can also be used to isolate vibration between ductwork and structural members.

Pros

- The gasket helps control sound traveling through structural components.

- Easy to apply to joists or studs.

- The gasket decreases vibrational and impact transfer.

- Reduces thermal movement, improving heating and cooling costs.

Cons

- Expensive.

Sound Dampening and Deadening

Green Glue Noiseproofing Compound

Green Glue Compound is a viscoelastic material that effectively controls sound transfer. It is often used between laminated sheets of drywall or other panel material. The compound acts as a vibrational barrier preventing up to 90% of sound transfer. It is effective at controlling low-frequency noise, as well as mid and high frequencies.

Green Glue Compound is a viscoelastic material that effectively controls sound transfer. It is often used between laminated sheets of drywall or other panel material. The compound acts as a vibrational barrier preventing up to 90% of sound transfer. It is effective at controlling low-frequency noise, as well as mid and high frequencies.

The noise proofing compound is easy to apply from tubes using a caulking gun, or a paddle if it’s in a 5-gallon pail. The compound can be applied to the white face of the first panel once it’s installed, and then sandwiched between a second gypsum layer.

Alternatively, apply it to the gray side of the second sheet, and then secure it to the first. Green Glue is my preferred viscoelastic compound for its ease of use and effectiveness at stopping sound penetration.

The manufacturer recommends 1 to 3 tubes per sheet of drywall. Although the cost sounds cheap at about 50-cents a square foot, that works out to an additional $16 per 4’x8’ drywall panel, which equates to one tube.

Using two is more effective at isolating sound, but will increase the costs too. You may want to use a power caulking gun to save your hand.

STC Rating: The rating depends on the construction of the wall or ceiling.

Best uses

Green Glue is effective for walls and ceilings at preventing sound movement. It can be used during construction, or post-construction when adding another sheetrock layer to an existing wall or ceiling.

Pros

- The compound prevents sound movement between wall and ceiling structures.

- Easily reduces noise by 70% to 90%.

- It deadens noise in all frequency ranges.

- Green Glue is easy to apply.

Cons

- Expensive.

- Need to use the thickness recommended for proper noise control.

- Can take 7 to 30 days to cure.

Acoustical Caulk/Sealant

Acoustic caulking is an elastic sealant that can be used to fill gaps, cracks, and holes to prevent sound from leaking through. There is often a gap between drywall panels, the floor, ceiling, other walls, and openings in the wall for windows or doors. Acoustic caulking can be used to fill those spaces to prevent sound vibration movement.

Acoustic caulking is an elastic sealant that can be used to fill gaps, cracks, and holes to prevent sound from leaking through. There is often a gap between drywall panels, the floor, ceiling, other walls, and openings in the wall for windows or doors. Acoustic caulking can be used to fill those spaces to prevent sound vibration movement.

The caulking is paintable, so it can be used around receptacle boxes, light fixtures, between door jambs and drywall, as well as around window frames to prevent noise penetration. When exposed to air, the surface forms a tough film, while staying pliable and flexible to prevent vibrational sound concerns.

The sealant can also be used to seal the vapor barrier membrane on interior partition walls.

A 29 oz. tube will do 3/8” bead of almost 90-feet. The manufacturer recommends doubling up the 3/8” bead to achieve a higher STC rating, so you’ll only get half the distance for the best results. The acoustical sealant is water-based, durable, and easy to use. It is well worth the expense.

STC Rating: Acoustic caulk has an STC of 53 when applied following the manufacturer’s instructions.

Best uses

Use acoustical caulking to seal all gaps, cracks, holes, and seams in your walls to stop noise moving through.

Pros

- Stops sound penetration.

- Easy to use.

- It has a high STC rating.

- Durable and long-lasting.

Cons

- Costly.

Anti-Vibration Mats

Anti-vibration mats are made of recycled rubber material that has been heated and compressed to form a dense sound dampening pad. It can be used to isolate impact and vibration transfer from appliance to decrease sound transfer.

Anti-vibration mats are made of recycled rubber material that has been heated and compressed to form a dense sound dampening pad. It can be used to isolate impact and vibration transfer from appliance to decrease sound transfer.

The pads are available in 1/4″, 3/8”, and 3/4″ thicknesses, the thicker being more effective at isolating noise movement. The rubber is waterproof, slip-resistant, and cushioning.

The anti-vibrational mats can be used under a washing machine, exercise equipment, or refrigerator, on the counter under a printer, microwave, or in the workshop under machines. The pad not only reduces vibrational noise, but it can also protect the floor, counter, or desk surfaces from damage.

The mat is also great outdoors under an air conditioner to prevent transfer noise vibration, or in the trunk or back of an SUV to decrease rattles, and sliding, or to give Fido some cushioning. Used in front of the sink or stove, it will mute footfall noise and decrease leg and foot fatigue.

Best uses

Use the anti-vibration mat in the home or office to decrease machine vibration or impact noise transfer. Additionally, it can be used to reduce leg and foot fatigue in the kitchen or under a desk.

Pros

- Quiets vibrational noise

- Prevents wear and damage to floor, counters, desks or tables

- Inexpensive

- Recycled material

- Decreases leg and foot fatigue when standing or sitting

Cons

- Mats have small holes or crevasses that collect dust and dirt

- May require assistance placing under some machines

- Some rubber tire smell

Anti-Vibration Floor Pads

Anti-vibration floor pads are 2-1/2” diameter, 5/8” thick pads that fit under the feet or wheels of appliances or machines to effectively control vibrational noise transfer. They are made of Sorbothane viscoelastic polymers and in addition to controlling noise, also prevent machines and appliances from traveling due to vibration.

Anti-vibration floor pads are 2-1/2” diameter, 5/8” thick pads that fit under the feet or wheels of appliances or machines to effectively control vibrational noise transfer. They are made of Sorbothane viscoelastic polymers and in addition to controlling noise, also prevent machines and appliances from traveling due to vibration.

The pads protect the floor from scratches or other damage and lift the appliance about 5/8-inch higher. They reduce vibration by about 94.7% and isolate the associated sound for less noise. The pads can be used under washers, dryers, dishwashers, fridges, exercise equipment, and other machines to control vibration and movement.

Best uses

Work well under household, business, exercise, and workshop machines to control vibration, appliance ‘walking’ and sound transfer.

Pros

- Controls vibration

- Prevents appliance travel due to vibration

- Decreases vibrational sound transfer

- Protects floors from appliance feet

Cons

- Expensive

Sound Deadening Paint

Sound Deadening paint helps to dampen acoustic ringing feedback in rooms. It is water-based, so clean-up is easy, and it can be applied with a sprayer, roller, or brush. There is also little odor and no VOC. The paint has microscopic ceramic particles and other fillers that absorb and decrease sound movement.

Sound Deadening paint helps to dampen acoustic ringing feedback in rooms. It is water-based, so clean-up is easy, and it can be applied with a sprayer, roller, or brush. There is also little odor and no VOC. The paint has microscopic ceramic particles and other fillers that absorb and decrease sound movement.

The paint is not a primer, but a flat finishing coat. A gallon will cover up to 150 sq ft, but it goes on thick and may need a second coat. It can be used on primed metal, wood, or plaster walls, and ceilings. The polymers in the paint also acts as a thermal barrier, reducing heat transfer through it.

Sound Control: Sound Deadening paint can decrease mid-range 500 Hz frequency noise by about 30%.

Best uses

Since the paint controls the mid-range of the human voice frequency, it is more suited for offices, meeting rooms, living, and recreation rooms.

Pros

- Reduces conversational feedback, tinning, and ringing

- Easy to use

- Fast clean-up

- Thermal transfer protection

Cons

- Expensive when calculating coverage. On average, latex paint covers up to 400 sq. ft. per gallon.

Soundproofing Barriers

Mass Loaded Vinyl

Mass loaded vinyl (MLV) is a heavy polymer that damps sound transfer. It is available in different thicknesses and dimensions.

Mass loaded vinyl (MLV) is a heavy polymer that damps sound transfer. It is available in different thicknesses and dimensions.

The thicker the material the better, and the greater the quantity purchased, the lower the square foot cost. MLV that is 1/16 thick weighs 1/2-pound and has an STC of 21, 1/8” is 1-pound with an STC around 27, and 1/4” is a hefty 2-pounds per square foot and scores between 31 and 32 on the STC rating curve.

MLV can be used in wall, ceiling, and floor construction to block sound, as well as in machine rooms, and automobiles to damp sound and vibration. It is also used around HVAC, ducts, pipes, pumps to control noise, and many other devices too.

The vinyl is durable and strong – it has a tear strength of 26psi. MLV can be tacked, nailed or screwed, so it is easy to install on existing partitions or new construction to damp sound. All seams need to be overlapped to ensure the barrier is complete.

STC Rating: 1/16” thick MLV has an STC of 21, 1/8” an STC of 27, and 1/4” is between 31 and 32.

Best uses

Mass loaded vinyl works well sandwiched between drywall layers, or drywall and studs, between the subfloor and the floor, hung on the wall or windows as a thick curtain, or in your vehicle to isolate noise.

Pros

- Effective independent noise control

- Easy to use

- Cuts with a utility knife or heavy scissors

- No odor

Cons

- limited or no color choice

- Heavy

Soundproof Underlayment

Noise Reduction Underlayment

Noise reduction underlay is an insulated felt mat of recycled material that absorbs impact noise and cushions the floor. It is 3mm or 4mm thick with a smooth plastic film on the upper side to allow laminated, engineered, or hardwood flooring to move and flex, and to prevent the passage of moisture.

Noise reduction underlay is an insulated felt mat of recycled material that absorbs impact noise and cushions the floor. It is 3mm or 4mm thick with a smooth plastic film on the upper side to allow laminated, engineered, or hardwood flooring to move and flex, and to prevent the passage of moisture.

The underlay has a 1-3/4” overlap and adhesive strip to secure other strips or rolls. Easy to install and cuts with a utility knife or scissors.

The underlayment comes in 3, 5, 8, and 10-foot wide rolls of differing lengths. The greater the surface area a roll covers usually means a lower per foot cost. The felt rolls over wood or concrete subfloors and reduces impact sound movement and sound transmission. The IIC is 67 and STC is 66, rates that indicate it will mute most footfall impact, conversation, and media noise, and furniture movement.

STC Rating: Noise-reduction underlay has an STC of 66 and an impact isolation class (IIC) of 67, which means it will mute walking and furniture sound transfer between floor levels.

Best uses

The noise reducing underlay provides very good sound control for laminated, hardwood, and engineered wood floors.

Pros

- Excellent sound and impact control ratings

- Easy to install

- Installation is simple

- Inexpensive ($0.32/sqft)

- Prevents floor creak and echo

Cons

- Need a sharp utility knife or scissors and some strength to cut

Cork Underlayment

Cork underlay can be rolled onto a concrete or wood subfloor and glued down or left loose. A 75-pound roller should be used to press the cork into the glue if it is being secured that way.

Cork underlay can be rolled onto a concrete or wood subfloor and glued down or left loose. A 75-pound roller should be used to press the cork into the glue if it is being secured that way.

The 1/4-inch (6mm) cork creates a membrane that decreases sound movement in both directions. It will even isolate sound penetration through cracks and crevasses. Cork can be used under hardwood, laminate, stone, marble, and ceramic tile.

The cork is easy to install and cuts with scissors or a utility knife. It is available in 4-foot wide rolls up to 100 feet long – probably longer if you can lift it. The unit cost varies with the total coverage. When used with a concrete floor, a vapor barrier is suggested, it isn’t necessary with a wood subfloor.

STC Rating: The rating for cork as an underlay over concrete is STC 52 and IIC of 51. If there is a suspended ceiling under the concrete floor, the STC goes to 60 and the IIC to 61.

Best uses

Cork underlayment works well under wood flooring, stone and ceramic floors on concrete or wood subfloors.

Pros

- Very good at reducing impact and sound transfer

- Prevents noise movement from both sides

- Easy to cut and install

- mildew and mold resistant

Cons

- Cork will crack if bent

Car Soundproofing

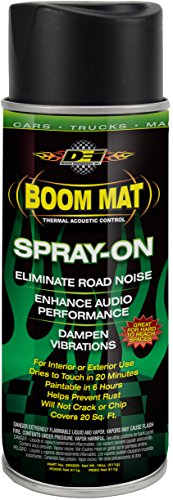

Sound Deadening Spray (DEI Boom Mat)

Sound Deadening Spray is a rubberized material that helps reduce vibrations, rattles, and squeaks in vehicles. Apply it to the metal inside doors, the trunk, engine compartment, wheel wells, and the underside to deaden sound.

Sound Deadening Spray is a rubberized material that helps reduce vibrations, rattles, and squeaks in vehicles. Apply it to the metal inside doors, the trunk, engine compartment, wheel wells, and the underside to deaden sound.

Several light coats will cure faster than a thick coat. The material is rated for temperatures up to 300F° but keep it off your exhaust system.

The spray is VOC compliant. However, a mask is recommended as is proper ventilation. Use the sound deadening spray in hard to reach spaces to stop vibration or road noise.

The material may take longer than the 6 hours to dry and can have strong odor until fully cured. Once dried, it can be painted. Additionally, the spray can reduce heat transfer into the passenger compartment.

Fatmat Sound Deadener

Fatmat Sound Deadener covers 50 square feet per roll. It is a rolled material that is self-adhesive on one surface and aluminum covered on the other. It is 0.46 PSF and 80mil thick, so has the mass and thickness to damp vibration and improve sound quality in your vehicle, boat, RV, or home.

Fatmat Sound Deadener covers 50 square feet per roll. It is a rolled material that is self-adhesive on one surface and aluminum covered on the other. It is 0.46 PSF and 80mil thick, so has the mass and thickness to damp vibration and improve sound quality in your vehicle, boat, RV, or home.

Although it is pliable, a heat gun or hair dryer may help form it into difficult areas to achieve complete contact.

The Fatmat comes with an installation kit of roller and knife, plus instructions. The roller and handle work well to ensure the sticky side contacts and sticks.

Ensure the contact surface is clean and free of oil for full contact, and the best sound vibration blocking. It can reduce road, engine, tire, and exhaust noise and improve the sound quality in the passenger cabin.

Dynamat Self-Adhesive Sound Deadener

Dynamat Sound Deadener is a self-adhesive sheet material with an aluminum backing that damps vibrational sound. It is 0.36 PSF and 67mil thick and pliable enough to mold over floors, door panels, and wheel wells. Dynamat will decrease road, engine, and exhaust sounds, improving the quality of sound in the passenger area.

Dynamat Sound Deadener is a self-adhesive sheet material with an aluminum backing that damps vibrational sound. It is 0.36 PSF and 67mil thick and pliable enough to mold over floors, door panels, and wheel wells. Dynamat will decrease road, engine, and exhaust sounds, improving the quality of sound in the passenger area.

The aluminum surface helps provide heat shielding so the mat can be used in the engine are to reduce noise. The sound deadener can also be used in boats, RVs, and in the home to help deaden appliance and sink noise.

Dynamat comes in rectangular mats for ease of use. An installation kit is available at additional cost to assist with installation.

Noico Sound Deadener

Noico Sound Deadener sheets are 80mil and 0.7 PSF. They are flexible self-adhesive butyl products that have an embossed aluminum shielding on one surface. When installed and rolled out correctly, the aluminum smooths out flat. The thickness and weight add to its ability to deaden road vibration and sound.

Noico Sound Deadener sheets are 80mil and 0.7 PSF. They are flexible self-adhesive butyl products that have an embossed aluminum shielding on one surface. When installed and rolled out correctly, the aluminum smooths out flat. The thickness and weight add to its ability to deaden road vibration and sound.

The sound deadening sheets are easy to cut, shape, and install. They need to be rolled smooth for full sound control benefit. It is recommended that gloves be worn when handling the butyl material.

Install in the trunk, wheel wells, floorboards, and firewall to reduce road and tire noise. Ensure the surface is clean and free of oil or grease for the best adhesion.

Noico Tape Finishing Sealing Tape

Finishing sealing tape has a foil surface and self-adhesive for sealing the edges of the butyl sound deadening sheets. It is 2mil thick and about 1-1/2” wide. It is designed for use in vehicles and will decrease sound and vibration between sound deadener seams.

Finishing sealing tape has a foil surface and self-adhesive for sealing the edges of the butyl sound deadening sheets. It is 2mil thick and about 1-1/2” wide. It is designed for use in vehicles and will decrease sound and vibration between sound deadener seams.

The tape cuts easily and helps reduce sound penetration. The tape has a reflective aluminum foil face but isn’t heat rated beyond 212F°. The adhesive is very sticky, so cut the tape into short lengths to trim edges and prevent sound leakage, and prevent the tape from sticking to you, itself, or other surfaces.

GTmat Sound Deadening Material

GTmat is a 50mil sound deadening material with a protective aluminum top layer. It comes with a degreaser, roller, and a couple of GTMAT decals. It adheres as soon as it is pressed into location, so cut to fix before peeling the adhesive cover. It works well on floors, doors, roof, and trunk. It is only rated to 112F°

GTmat is a 50mil sound deadening material with a protective aluminum top layer. It comes with a degreaser, roller, and a couple of GTMAT decals. It adheres as soon as it is pressed into location, so cut to fix before peeling the adhesive cover. It works well on floors, doors, roof, and trunk. It is only rated to 112F°

The material will damp engine and road noise, and seal areas where air and sound can penetrate the body. A roll is about 10 square feet, so calculate what you need, so you have enough. GTmat can also help prevent components from vibrating against each other and creating noise.

Window and Door Sound Insulation

Window and Doors Weather Stripping

Window and door weatherstripping is Double-D profile rubber foam that can be used to compression seal windows and doors to keep weather and sound out. The foam has a self-adhesive backing strip for securing to window and door frames. Since most sound penetrates through the frame, not through the glass, the seal improves sound control.

Window and door weatherstripping is Double-D profile rubber foam that can be used to compression seal windows and doors to keep weather and sound out. The foam has a self-adhesive backing strip for securing to window and door frames. Since most sound penetrates through the frame, not through the glass, the seal improves sound control.

The vinyl door sweep compliments the Double-D strip. It is 43.3” long and has a self-sticking strip to attach to the bottom of the door and keep weather, sound, insects, and rodents out.

The sweep is easy to cut to fit all door widths. The flexible sweep is usually for exterior doors but can be used on interior doors to decrease flanking noise under the door.

Door Draft Stopper

Door Draft Stopper is a two-pack of 39” long door sweep. It is made of silicone and provides a flexible bottom seal for most doors. Composed of 3 silicone layers it is also waterproof, so won’t wick moisture into the door. The layers baffle weather and sound and improve energy efficiencies.

Door Draft Stopper is a two-pack of 39” long door sweep. It is made of silicone and provides a flexible bottom seal for most doors. Composed of 3 silicone layers it is also waterproof, so won’t wick moisture into the door. The layers baffle weather and sound and improve energy efficiencies.

Draft stoppers are easy to cut and install. They adhere to the inside bottom of the door to keep weather and sound out, as well as bugs and rodents.

The draft stopper works well for single dwellings and apartments and can be used on exterior and interior doors. The adhesive will bond to wood, metal, glass, and plastic doors.

Soundproofing Installation/Construction Materials

Panels

There are different brands, composition, thicknesses, and densities of gypsum board. The mass or density is an integral part of the four interconnected principles of sound control.

The cost of materials versus the soundproofing return is always a consideration too. For a deeper comparison of the soundproofing abilities of drywall and QuietRock, check out this post.

Drywall

Drywall is sheets of compressed gypsum covered in heavy paper. The long edges are usually tapered to provide a smooth finish when taped and mudded. It is commonly known as drywall, gypsum, plasterboard, wallboard, and the brand name Sheetrock.

It comes in 1/4″ up to 1” thicknesses, and is 4’ wide and between 8 and 12 feet long, although long sheets are available. The STC of drywall depends on the materials used to construct a wall or ceiling. Normal construction uses 1/2″ thick material, while 5/8” is common for soundproofing applications.

Different gypsum panels are available and have different uses. White Board or regular is commonly used in construction. Green Board is moisture resistant, Blue Board is more retardant to water and mold, and Purple is even better – it’s good for bathrooms.

Paperless Gypsum is even more resistant to moisture as there is no paper to draw it in. Type X has a higher fire-resistant rating. Soundproof or SoundBreak XP is denser due to a layer of soundproofing viscoelastic polymer sandwiched between 2 high-density gypsum layers – it can improve the STC by 15 to 20 points over standard panels and costs approximately $62.50 a sheet.

QuietRock

QuietRock is a brand of soundproofing drywall. It has a viscoelastic core between two layers of gypsum. The mass of the drywall stops soundwaves, and the core damps vibration pushing the STC up 15 to 20 spots compared to White Board.

The panels are available in thicknesses of 1/2″, 5/8”, and 1-3/8”. It has the tapered edges like common drywall and comes in 4’ wide sheets 8’, 9, 10’, or 12’ long.

QuietRock has different soundproofing panels. EZ-SNAP is 5/8” thick and installs like common drywall; it is between $60 and $65 a sheet. There is an EZ-SNAP mold-

resistant panel too. QuietRock 510 is only 1/2″ thick, 530 is 5/8” gypsum and denser than the EZ-SNAP, so better at blocking sound, and QuietRock 530RF blocks radio frequencies for security applications. The 545 panel has 11 layers and is 1-3/8” thick, weighs 200-pounds, and blocks even low-frequencies. It has applications for theaters, sound rooms, and studios.

Recessed Light and Speaker Cover

Recessed lighting and ceiling or wall speakers create holes through which noise can travel. Recessed covers made of mineral wool, are fire resistant, block against drafts and sound, and are easy to install and seal with acoustic caulking. The covers help protect the fixture from surrounding insulation and prevent cold spots in your ceiling, improving the thermal barrier.

Recessed lighting and ceiling or wall speakers create holes through which noise can travel. Recessed covers made of mineral wool, are fire resistant, block against drafts and sound, and are easy to install and seal with acoustic caulking. The covers help protect the fixture from surrounding insulation and prevent cold spots in your ceiling, improving the thermal barrier.

Improvement in the thermal barrier usually translates into improved sound control. The recessed covers provide a barrier that can be sealed to stop air and sound leakage, plus allow insulation to cover the fixture without concern of electrical fires.

The improvement to the thermal barrier translates into less sound transfer and flanking noise movement, helping to improve the sound quality.

Putty Pads

Putty Pads are made of non-flammable calcium borate and come in 1/4″x7” square peel and stick sheets. The flexible sheets are sized to wrap electrical boxes used for receptacles and switches. The pads are inexpensive (50 to 60 cents each) and easy to install in construction or renovation situations, but not in post-construction applications.

Putty Pads are made of non-flammable calcium borate and come in 1/4″x7” square peel and stick sheets. The flexible sheets are sized to wrap electrical boxes used for receptacles and switches. The pads are inexpensive (50 to 60 cents each) and easy to install in construction or renovation situations, but not in post-construction applications.

The pads are flexible and stick to the electrical box, and everything else, so make sure the area is clean and maybe pre-fit before peeling the protective layer off. It can be cut with a utility knife or torn.

You may find it easier to wrap the boxes before installation. Putty Pads have an STC of 49 when coupled with the proper wall construction and acoustic caulking.

Wall Plate Insulation Gasket

Wall plate insulation gaskets are peel and stick foam pads that block air and sound leaking through the switch or receptacle. The peel and stick will stop the gasket from shifting and helps seal it.

Wall plate insulation gaskets are peel and stick foam pads that block air and sound leaking through the switch or receptacle. The peel and stick will stop the gasket from shifting and helps seal it.

The insulation seals the gaps around the electrical box and drywall, plus the space around the receptacle or switch in the box.

The gaskets work for outside wall outlets and switches, but can also be used to stop sound movement through the outlets – a common location for sound leakage. The wall plate insulation doesn’t seal the plug prong holes in the receptacles. If you feel air moving through those holes, plug something in, or use child safety plugs. A great idea for apartment dwellers!

What to Look for When Choosing Soundproofing Materials (Buyer’s Guide)

The first thing you need to do when soundproofing is to determine what noises you are trying to control. Airborne noise echoes or reverberates within your media room or travels through the wall and ceiling partitions.

Impact noise could be from a ball bouncing outside or people walking on the floor above. Flanking noise sneaks under doors or through the ductwork so is more difficult to isolate.

Once you identify the type of sound, you need to control, decide what you want, need, or can do to improve the level of noise disturbance. Taking walls and ceilings apart can be expensive and messy.

Adding more building materials to a partition can be less expensive but still messy. Alternatively, purchasing or making sound controlling products may be an effective solution.

The next thought is how much sound you need to control. If you just wish to control the sound quality in a media room, then acoustic panels, diffusers, and traps may do the job.

Reducing sound movement through partition walls or ceilings is a bigger task, often involving construction or deconstruction and reconstruction to improve sound control.

An STC of 40 is the beginning of privacy, loud talking is still audible, but muted. Improving the STC to 50 will quiet even loud voices so they can’t be understood. An STC of 60 is considered excellent, suppressing even loud noises like musical instruments. The more the STC needs to be raised, the greater the cost involved.

When soundproofing, I recommend choosing materials or products that are durable and easy to work with. They should be thick or dense enough to block sound movement or have enough porosity or insulation property to absorb sound.

You also want them to be readily available in the amount required – having to wait for anything is frustrating. Lastly, make sure that what you are getting is worth the cost. If it only improves the STC by 2 points, don’t pay too much.

One last consideration is if you need to improve energy efficiency as well as control sound penetration. Exterior walls, windows, and doors can be improved to do both.

Whether insulating around the openings, replacing with insulated windows or doors, or hanging dense multi-layered thermal curtains, preventing air movement will also improve sound control. Adding insulation, resilient clips and channels, Green Glue, and double layers of drywall will improve exterior walls too.

Conclusion

Sound control is an important part of relaxing and enjoying wherever you are. Whether you own or rent, hopefully, you found something helpful in this review.

When making a product decision, make sure the cost supports the soundproofing benefit. Some products are great for post-construction application, and some are better during construction or renovations. If you found the information helpful, let us know.

If you know someone who might find it interesting, pass it on. As always, your comments and suggestions are appreciated.

Wow! Thanks for sharing these budget friendly materials. I really love how detailed you are with this Eugene. This is the blog that I am following!

Love the information provided, do you have any plans on working out fence insulation that does not involve a brick fence? I live on a main road at an intersection and would love to be able to build a sound barrier fence. I was thinking some sound proof insulation sandwiched in-between fibre cement sheeting. Do you think this would be a viable option?

This is great stuff. Keep up the good work!

Hi Josh,

Glad you liked it.

Thanks,

Terry

Much appreciated! Thank you for so generously and articulately sharing your knowledge!

Hi Karen,

Your welcome. Hope it is helpful.

Terry

Hi

thanks a lot for your great list. it’s helpful

but I have a question.

comparing between 3 material… cork density 190kg/m3 (11.89 lb/ft3) and cork density 120kg/m3 (7.49 lb/ft3 ) and rockwool density 50kg/m3 ( 3.12 lb/ft3)

how can I choose whick one is the best to reduce or block the sounds between 2 rooms wall ???

Great article and I appreciate the links to the products. Im in the process of sound proofing my bedroom from outsidd noise. What are your thoughts on Sonopan (sold at Home Depot)? Would you use it or stick with Quietrock?

Hi Bill,

I have no experience with Sonopan so I may not be much help. I went to their website to take a look just to get annoyed. Looking at the STC specs they have for wall assemblies was not much help because they did not really compare apples to apples. Started off with a hollow wall at STC 32 then added insulation, Sonopan, resilient channel, and double 5/8 drywall to get to STC 56. By adding the resilient channel and double 5/8 they muddy the waters. What I know is that adding Mass Loaded Vinyl and plain 5/8 drywall can get you to STC 49. Adding double 5/8 with Green Glue sandwiched between can get the STC over 50. Using either of those and QuietRock will be even better.

If it were me, I would stick with QuietRock unless I could get more information on the Sonopan.

Terry

Thanks Eugene! A really thorough analysis. So very helpful.

Question, I have read that clay is an excellent sound barrier, even finding some clay based paint and wall finishes. What do you think about non-toxic clay materials? And do you have any specs on them?

Thanks you.

Hi Alex,

After reading your email, I did a quick search because I have no personal experience with clay soundproofing. It looks like a pretty good product at first glance. I will have to spend a little more time checking it out. I did not check out the paint because I am always dubious of paint as soundproofing.

Thanks for the information,

Terry

Hi Eugene,

You have tons of great info and great insights. It was very enjoyable to dig into and read your recommendations and learn more. I am renovating my 850 sq ft condo floor and have tenants below with a loud stereo / sub woofer. The apt has 10 ft ceilings so I am wiling to give up 2- 3 inches to stop the boom boom noise. Do you have any recommendations on best floor soundproofing? I will use your recommendations above for the walls. Is there an optimal sequence of floor products? For example, I am thinking of putting down a layer of 1/4 inch plywood over the exposed 1920’s subfloor with nails, then a layer of 5/8 inch sheetrock to add mass using green glue, then apply 1/4 inch MLV using Green Glue, then tongue and groove plywood with GG on the MLV without any nails, then noise reduction underlay, and luxury vinyl on top. I know, it sounds crazy and maybe an overkill but I read that mass can block low sound frequency and using multiple layers of different materials using green glue can really help. Any better approach to block sound without adding too much weight? Gypsum poured onsite 1.5 – 2 inch is too heavy according to my contractor. Thank you in advance for providing clarity to my crazy thought. 🙂

Hi Steve,

A couple of things. Green Glue needs to be applied to rigid surfaces, so it will not work well on the MLV. 1/4″ plywood is pretty flimsy, so I would not use it as a base layer. 1/4″ MLV is pretty heavy, and so is drywall.

This would be my overkill suggestion:

3/4″ T & G plywood glued and screwed to joists (to eliminate squeaks)

Green Glue

3/4″ T & G plywood (make sure not to overlap joints)

QuietWalk Plus Underlayment

Luxury Vinyl

I know that the plywood is heavy, but it will add as much mass as drywall.

Terry

Thank you all, but I’m still a little confused. I live in Australia and have recently bought an air compressor for my workshop. I live in a residential area and naturally, the compressor turned out to be very noisy when the motor is running, you have to yell when it’s running. I’d like to put it in a sound dampening cupboard. The products mentioned here leave me in a bit of a quandary. I guess I’d need an STC of some where between 40 and 50. Hope you can help.

Hi Jacqui,

One of my soundproof box ideas would be:

3/4″ plywood exterior

2 x 4 studs

Roxul rockwool soundproof insulation

Mass Loaded Vinyl on the insides of the studs

3/4″ plywood interior

Extend hose fittings and plug to exterior of box

Extend air intake to exterior of box

For more idea please see our article 17 Ideas on How to Build a Soundproof Box for Air Compressor.

Terry